Author: Matt Del Fiacco

Modern brewers continue to push the envelope when it comes to packing as much hop character as possible in their beer, which is typically accomplished by adding large doses of hops either during or after fermentation. These dry hop additions allow for the extraction of aromatic oils without increasing bitterness, at least too much, as the beer is far below the temperature required to isomerize alpha acids.

One thing brewers have to consider when making a dry hop addition is the temperature of the beer. It’s commonly recommended that dry hops be added to beer at fermentation temperature, somewhere around 68°F/20°C, which is widely believed to lead to the extraction of more hop oils. However, there’s some evidence suggesting cooler dry temperatures may actually be beneficial in that it reduces polyphenol extraction while having little impact on anything else.

In reading through Scott Janish’s The New IPA, I found the discussion on dry hop temperature particularly interesting and was reminded of a past xBmt where tasters were able to distinguish beers dry hopped at different temperatures. I don’t dry hop often, so this isn’t something I’ve thought much about, and it seems opinions vary quite a bit as to which approach is best. With a hoppy ale on deck and unable to collect data from tasters due to being quarantined, I figured I’d revisit the variable of dry hop temperature to taste any differences for myself.

| PURPOSE |

To evaluate the differences between a Double IPA dry hopped at 38°F/3°C and one dry hopped at 66°F/19°C.

| METHODS |

I went with a Double IPA with a considerable dry hop addition for this xBmt, as I felt it would best display any differences caused by the variable.

Some Like It Hot

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.2 gal | 60 min | 74.6 IBUs | 7.4 SRM | 1.079 | 1.012 | 9.0 % |

| Actuals | 1.079 | 1.014 | 8.7 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, 2 row (Gambrinus) | 12.25 lbs | 84.48 |

| Caramel/Crystal Malt - 60L | 8 oz | 3.45 |

| Vienna Malt (Gambrinus) | 8 oz | 3.45 |

| Sugar, Table (Sucrose) | 1.25 lbs | 8.62 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 24 g | 60 min | Boil | Pellet | 12 |

| Cascade | 62 g | 25 min | Boil | Pellet | 5.5 |

| Cascade | 69 g | 5 min | Boil | Pellet | 5.5 |

| Citra | 60 g | 5 min | Boil | Pellet | 12 |

| Cascade | 48 g | 5 days | Dry Hop | Pellet | 5.5 |

| Citra | 48 g | 5 days | Dry Hop | Pellet | 12 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 75% | 60°F - 72°F |

Notes

| Water Profile: Ca 80 | Mg 2 | Na 10 | SO4 125 | Cl 62 |

Download

| Download this recipe's BeerXML file |

After collecting two identical volumes of water on brew day, I turned the elements on to heat them up.

Next, I weighed out and milled identical sets of grain for each batch.

Once the water was properly heated, I incorporated the grains then checked to ensure both batches were at the same mash temperature.

With each mash complete, I removed the grains and brought the worts to a boil.

When the 60 minute boils were finished, I homogenized the worts by racking half of each through a CFC on their way to fermentation kegs then took refractometer readings confirming both hit the same intended OG.

The filled kegs were placed in my fermentation chamber where they were allowed to finish chilling .

I proceeded to use remnant wort from each batch to make starters of Imperial Yeast A07 Flagship, which got pitched the following morning.

Neither beer was showing signs of activity after 8 days at 66°F/19°C, so I moved one to a separate chamber controlled to 38°F/3°C and left it overnight to stabilize before adding dry hops to both batches.

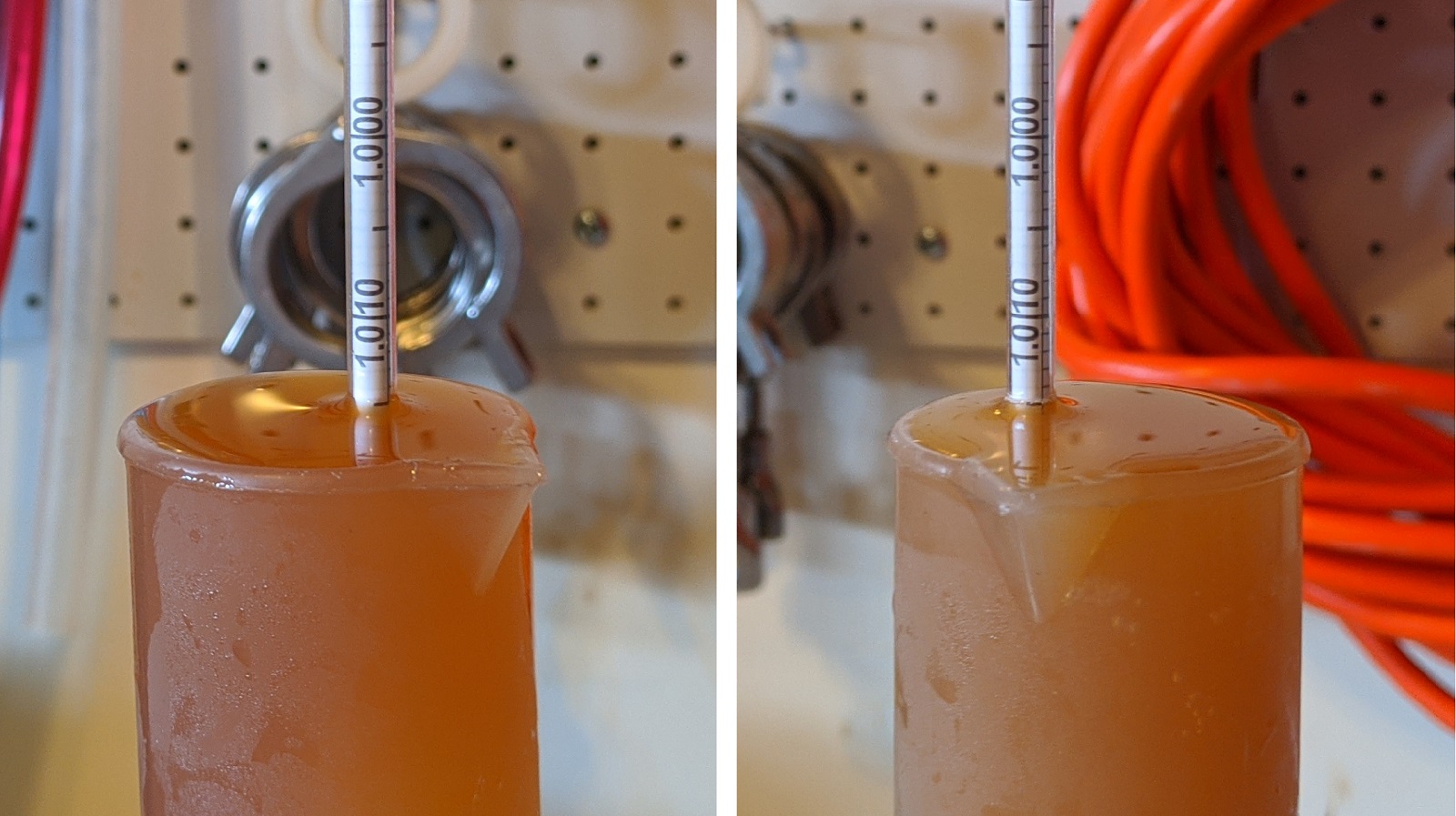

The beers were left alone at their respective temperatures for 3 days, after which I removed the dry hops and cold crashed both to 33°F/1°C. Hydrometer measurements taken the following day showed the beers had reached the same FG.

At this point, I pressure transferred the beers to sanitized serving kegs.

The filled kegs were placed in my cool keezer where they were burst carbonated and left to condition for a couple weeks before they were ready for evaluation.

| RESULTS |

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer dry hopped cool while the other set was filled with the beer dry hopped warm. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, though I did so just 6 times (p=0.08), indicating my inability to reliably distinguish a Double IPA dry hopped at 38°F/3°C from one dry hopped at 66°F/19°C.

Prior to evaluating these beers, I was pretty convinced I’d be able to tell them apart, but they ended up being nearly identical in every respect. To me, both had an abundance of citrus aroma with hints of pine and resin. The malt character was present and helped support the hop character, though if I were to brew this recipe again, I’d dial back the crystal malt a bit.

| DISCUSSION |

Few would question that idea that dry hopping is the best way to impart beer with heaps of hoppy goodness, hence the reason brewers rely on it so often when making various types of IPA, among other styles. It’s common for dry hop additions to be made to beer at standard ale fermentation temperature, though recent studies suggest cooler temperatures may result in similar extraction of oils while reducing undesirable polyphenol extraction. Curiously, I was unable to reliably tell apart a Double IPA dry hopped at 38°F/3°C from one dry hopped at 66°F/19°C.

One explanation for these results is that I simply don’t have the palate to distinguish subtle differences in polyphenol levels in hoppy beers, as both samples tasted identical to me despite knowing full well what to look for. However, it’s also possible some other factor was at play, for example, dry hop duration or perhaps even the hop varieties I used.

In the rare times I brew beers that call for a dry hop addition, I add them toward the end of fermentation with the hope any oxygen introduced will be scrubbed from the beer. Considering I’ve never noticed an issue with polyphenols in my dry hopped beers, and I was unable to tell apart the beers in this xBmt, I have no plans to start chilling my beer before dry hopping.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

29 thoughts on “exBEERiment | Impact Of Beer Temperature When Dry Hopping A Double IPA”

It would be interesting to see whether dry hopping at higher temperatures, such as you might use to ferment a kveik brew, would have any effect.

i added DH at 88 recently for 3 days, before cold crashing. resulted in little aroma. sweet spot seems to be upper 60’s to get most aroma. but is the hop’s beta acid percentage more important during DH?

I’ve been using various kveiks this past year or so. I’ve suspected for a while that dry hopping at high temperatures was contributing to the haziness of my formerly-clear beers. So I started dry hopping below 50f these past 3 or 4 batches (PAs and IPAs).

The fact is that there’s no difference in the beers–clarity or flavor wise.

I’ve started to transition back to standard yeasts for my PA and IPAs and still using kveks for my lagers – which turn out crystal clear with no dry hopping.

Interesting, Jim. I used Lallemond Voss in my most recent commercial IPAs . With only 10% wheat and 10% flaked oats and 3lbs per bbl dryhop, I expected a more lighter haze than a typical NEIPA. However, even with a long cold crash, both maintain a deep haze. I am curious if the dryhop during active fermentation vs near terminal would have an impact. I am brewing a hoppy wheat (Sabro) with Voss this week and am likely going to dryhop near terminal vs active.

anecdotally it has for me. I’ve dry-hopped at using Kviek yeast in the mid-high 90s and I did not like the flavor – much grassier and astringency. May have been other things at play but I personally stopped DHing Kveik fermented beers during active fermentation and moved Dhing to the keg post fermentation only and enjoy that better.

I’ve made a few hoppy kviek beers. My instinct was to shorten the dry hop duration with the higher temperatures, so they were dry hopped for only 24 hours (give or take). This worked great in those beers, but I was also using very ‘idiot proof’ hops (citra, mosaic, nelson, etc).

That’s so close to significance though. An alpha at .05 is used mainly in university settings or because that’s the way it’s always been done. With an alpha at .10 it would be significant. Just sayin.

That being said once you knew the difference did you like one over the other?

Dustin, if you are arguing that this result should establish that the beers tasted different, then what are we to make of the 4 trials (40%) where the wrong beer was selected!

First time comment(er) here. Exciting.

Scott Janish also discusses the affects of DH amounts and how increased quantities can lead to different flavors (for Cascade more DH leads to herbal/raw hop flavors). With this in mind, he recommends trying to split DH charges to 4-6 g/L (for Cascade at least). In your 5 gallon (18.9L) batch there was about 5 g/L which falls into the sweet spot.

It could be interesting in future xbmts to ‘overdo’ the hop amounts to intentionally try to set the stage for that extra herbal/raw character and see if the temp differences affect things.

We see some ridiculous amounts of DH being used in the hazy/tropical IPAs cooking out these days, so the extra DH wouldn’t be all too different from what many brewers are doing.

“That’s so close to significance though.”

Yes, but this isn’t horseshoes. Under the parameters they’ve elected to work under, they cannot conclude that there is a difference between the beers. If you want to conclude otherwise, you are welcome to do so.

I hate to be “that guy” but one thing that’s been bugging me for a while is that you guys are using grams instead of ounces for your hop additions (and still use pounds instead of kg) so I’ve really only the vaguest notions of what amounts you’re using. Signed, That Guy

LMAO this is one of the funniest things I’ve read all day. I know what you’re saying though but it still made me laugh, “that guy”.

Side note – I am going to start measuring in grams as well. I might just switch everything to metric. The longer I brew, the more metric makes sense to me for relating ingredients between different recipes and styles.

I absolutely agree. I wish I did metric, but my recipes are all in ounces.

And to top it off, they use IMPERIAL yeast. Why not metric???

I hate being “that other guy,” but I have no idea what are the amounts of grain they use. How many inches in a fluid pound, and other American riddles.

Hah! Touche!

There are 17.5 inches in an Imperial fluid pound, 13.25 in an American fluid pound; of course in mountain cities, like Denver, Colorado, you’ll need to add an inch or two to account for the low pressure.

I thought that was super odd too. I’m metric all the way, my brain doesn’t do American Standard at all.

I always thought surely it wouldn’t be too hard here to have a convert toggle to show measurements in either standard to make the page more globally friendly?

And the rest of the world is in your boat when imperial units are used, although it’s pretty easy to convert once you know the basic unit conversions tbh. Fahrenheit though, that sucks.

Don’t know why they don’t put the alternative in brackets depending on what they use.

When dry hopping, there’s no practical way to avoid O2 ingress. At least when dry hopping warm, there’s some yeast still in suspension that might be able to mop up some of the introduced O2. I’m not sure this actually happens, but it definitely doesn’t happen when dry hopping a 38-degree beer. So O2 damage might manifest more quickly and noticeably on a cold-dry-hopped beer. On the other hand, don’t have to worry about hop creep when dry hopping cold. As always with brewing, there are trade-offs…

I have spike conicals and brew NEIPAS all the time. I was worried about O2 ingress so I created my own airlock out of a butterfly valve, sight glass and gas manifold to mitigate the issue. Process is: Close butterfly, add hops to sight glass, attach gas and purge/displace o2 with co2, open butterfly valve and dump in hops. Done!

https://drive.google.com/file/d/1RqgaxiOB-vhZpReShatV9eNDn61hSlOW/view?usp=sharing

Here is a much talked about article by BSG re the benefits of the 34-39f, 24-48 dry hop. It finds maximum linalool extraction in less than 48 hours. https://bsgcraftbrewing.com/reevaluating-dry-hop-techniques

Would not be the cause that you dry hop for too long (5 days) making the variable temperature of little significance?

Citing the same book from Scott: there are different studies showing that maximum extraction for geraniol, linalol and thiols are at 24-48h. Same target for polyphenols. At lower temperatures polyphenols are extracted at a lower rate but there is still reasonable linalol extraction, for instance. So lower dry hop temperatures would help on extracting what we want and slowing down what we do not want.

But them if you leave it for too long it might be the case that polyphenol level reaches some sort of threshold where it masks other oils and leaves “no statistic diferences” in final flavor…

The recipe says a 5-day dry hop, but your procedure says 3 days. Which did you do?

The boys at Experimental Homebrewing brought this up a couple of months back. I tried something similar to your experiment a while back and also found little difference between the cold dry hop and the warm but over time I favored the warm. I was shocked hearing you don’t dry hop that often!! I have very few beers “I don’t ” dry hop! I even dry hop pilsners for more saaz flavor. Anywho love the exbeeriment.

1.69 ounces for a dry hop in a DOUBLE IPA is laughable .

That is a pale ale at the least . Either way , I’ve dry hop at low 70s and when using a Kveik yeast high 80s / low to mid 90s even and once the beer is cold crashed and kegged , you would never know .

Cheers

Isn’t 98 grams for 5.2 gallons (19.6 liters) quite in the lower end when it comes to a Double IPA? Do you think the result would be different if you used more dry hopping?

Although I find the results somewhat surprising when I consider my own experience with cold dry hopping. Then again there are som many factors that can influence the outcome that I really shouldn’t bee surprised. Like some mentioned that a shorter contact time, perhaps 1 or 2 days instead of 3 could alter the results. The choice of hops using cryo hops instead of T90 could alter the results.

If you are basing your xBmt on Scott Janish’s The New IPA book you could also read chapter 4 where you could read that higher sulfate levels reduced perceived hop flavor. Maybe the choice of a dry west coast IPA was not the best style to test (short and) cold dry hopping.

Janish points out that most of the effect of DH happens in the first 10 hours. He also suggests that agitation of the hops in a cold solution is the most promising method. I recently dry hopped in keg at 38F shaking every two hours and tasted as I went and pulled the bag after 8 hours having shaken it 4 times. Super quick and a grass/veg-free very floral character.

Heater failed on chronical fermenter during primary (temp drop 68 to 55F) over 7 days. As result DH (1 lb hop in 1/2bbl) will be at 55F for 3 days (30 min agitation). Always DH at 68-70F so this will be a first. Your xBmt here (38F DH) gives me confidence my scenario will have similar results.