Author: Marshall Schott

I became legally able to drink in March of 2002 and immediately began hanging out a local bars with friends who almost always ordered beer by the pitcher. It was during these outings that I was first introduced to more flavorful craft beer, as someone in our group would inevitably order a pitcher of either the locally popular Mac & Jack’s African Amber Ale or New Belgium Fat Tire. Indeed, back then, American Amber Ale was a style viewed by many as the quintessential “microbrew,” it was everywhere, including nearly every craft brewery I frequented at the time.

Nowadays, this doesn’t seem to be the case. It’s not uncommon for a brewery taproom or pub to be absent of this classic style, or refer to what is ultimately a Red IPA as an Amber Ale. I suspect this paucity is likely a function of the boom in hoppy styles, which while completely understandable, is a bummer for those of us who appreciate the classic flavors of a good American Amber Ale, which the BJCP provides the following description of:

An amber, hoppy, moderate-strength American craft beer with a caramel malty flavor. The balance can vary quite a bit, with some versions being fairly malty and others being aggressively hoppy. Hoppy and bitter versions should not have clashing flavors with the caramel malt profile.

It’d been nearly 2 years since I last made an American Amber Ale, and with so few options available locally, I took it upon myself to satiate my thirst. While my past few batches have varied slightly in terms of ingredients and methods, I followed a pretty standard brewing approach. For this particular batch, however, I opted for a less structured brewing approach.

| BREWING THE BEER |

I took inspiration from contributor Ray Found, who spent months perfecting his Make America Amber Again recipe, which favors a more balanced profile.

Short & Shoddy American Amber Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.2 gal | 25 min | 74.9 IBUs | 14.8 SRM | 1.054 | 1.012 | 5.6 % |

| Actuals | 1.054 | 1.009 | 5.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta American-style Pale Malt (Mecca Grade) | 9.5 lbs | 77.95 |

| Metolius Munich-style Malt (Mecca Grade) | 1.5 lbs | 12.31 |

| Crystal, Medium (Simpsons) | 14 oz | 7.18 |

| Pale Chocolate Malt | 5 oz | 2.56 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 13 g | 25 min | Boil | Pellet | 12.9 |

| Cascade | 55 g | 15 min | Boil | Pellet | 7.2 |

| Amarillo | 40 g | 15 min | Boil | Pellet | 10.2 |

| Centennial | 20 g | 15 min | Boil | Pellet | 9 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| House (A01) | Imperial Yeast | 74% | 62°F - 70°F |

Notes

| Water Profile: filtered Fresno tap water with a sprinkling of gypsum |

Download

| Download this recipe's BeerXML file |

The night prior to brewing, I filtered the full volume of brewing water into my kettle.

As the water was flowing, I tossed in an unmeasured amount of gypsum in hopes of increasing the impression of crispness in the beer.

Finally, I weighed out and milled the grain directly into the BIAB fabric filter.

At 2:50 PM the next day, I got started by setting the electric controller to heat the brewing liquor.

When the water was properly heated, I incorporated the grist then checked to ensure it hit my target mash temperature.

The mash was left alone for a brief 30 minutes, during which I stirred it every 10 minutes or so.

While the mash was resting, I measured out the kettle hop additions.

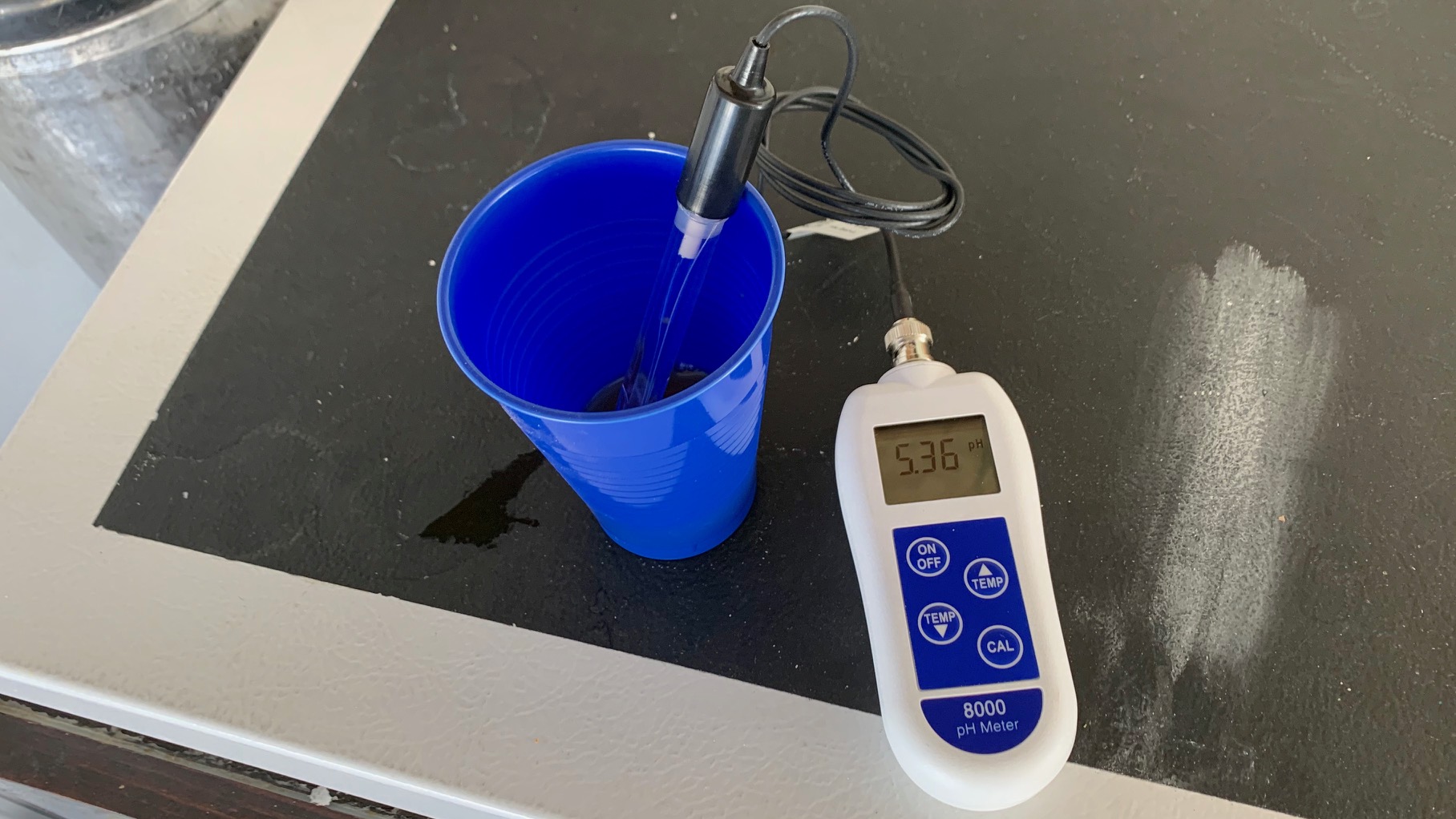

Out of curiosity, given my lack of precise water chemistry adjustment, I measured the mash pH about 15 minutes into the mash rest.

Following the short mash rest, I removed the grains then proceeded to bring the wort to a boil, which lasted only 25 minutes.

At the completion of the boil, I quickly chilled the wort with my IC.

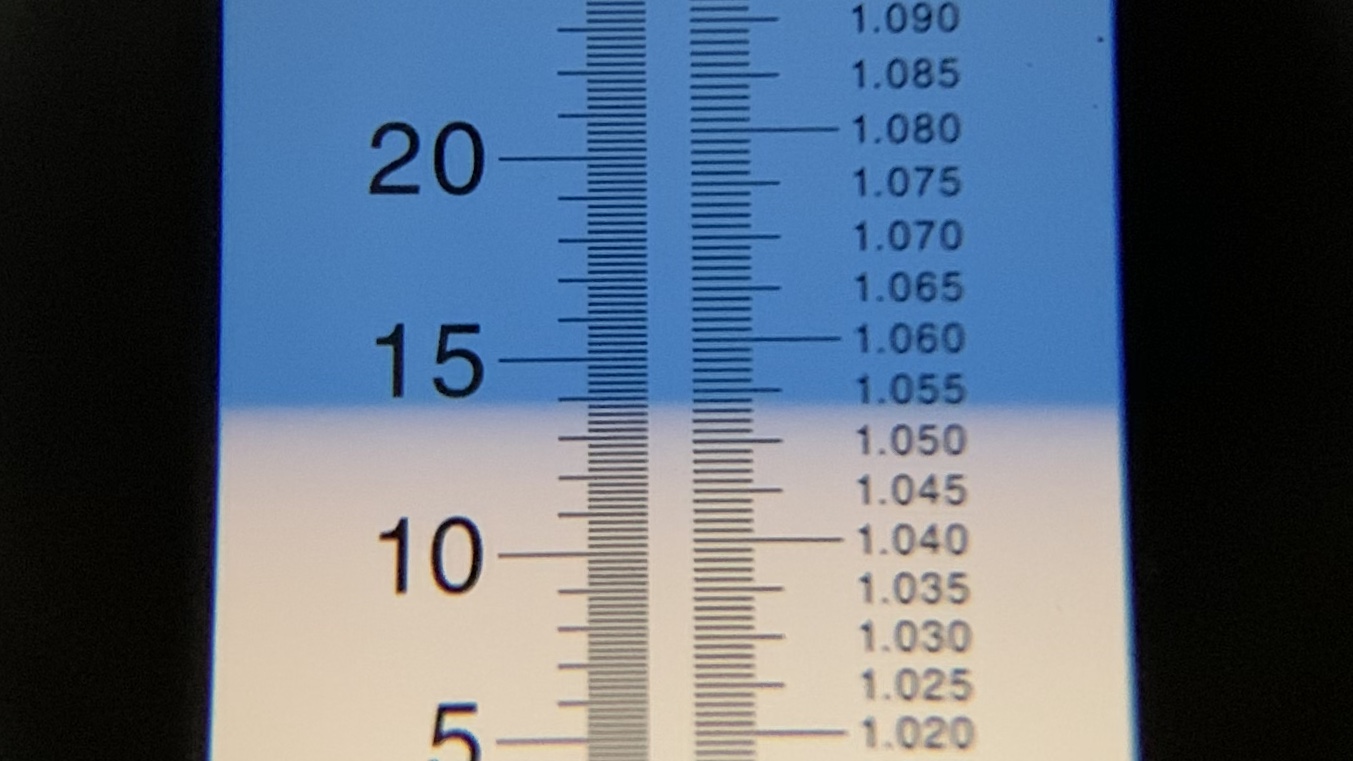

A refractometer reading showed the wort was at my target 1.054 OG.

I then immediately racked 5.5 gallons/21 liters of unsettled wort to a sanitized fermentation vessel. Given my relatively warm groundwater temperature, the wort was at a balmy 73°F/23°C when I pitched the single pouch of Imperial Yeast A01 House.

The filled fermenter was placed in my chamber controlled to 66°F/19°C and hooked up my CO2 capture device. It was 4:23 PM, barely 2 hours since I started brewing this batch.

When I returned to check on things less than 3 hours later, fermentation was already going nuts. After 3 days, I bumped the temperature to 73°F/23°C and it let the beer finish up for a couple more days before taking a hydrometer measurement confirming FG was reached.

At this point, I dropped the chamber temperature to 33°F/1°C for cold crashing. After 15 hours, I fined the beer with gelatin then left it alone 2 more days before transferring it to a naturally purged keg.

The filled keg was placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. I allowed the beer to condition for just 1 week before serving it to tasters for evaluation.

| RESULTS |

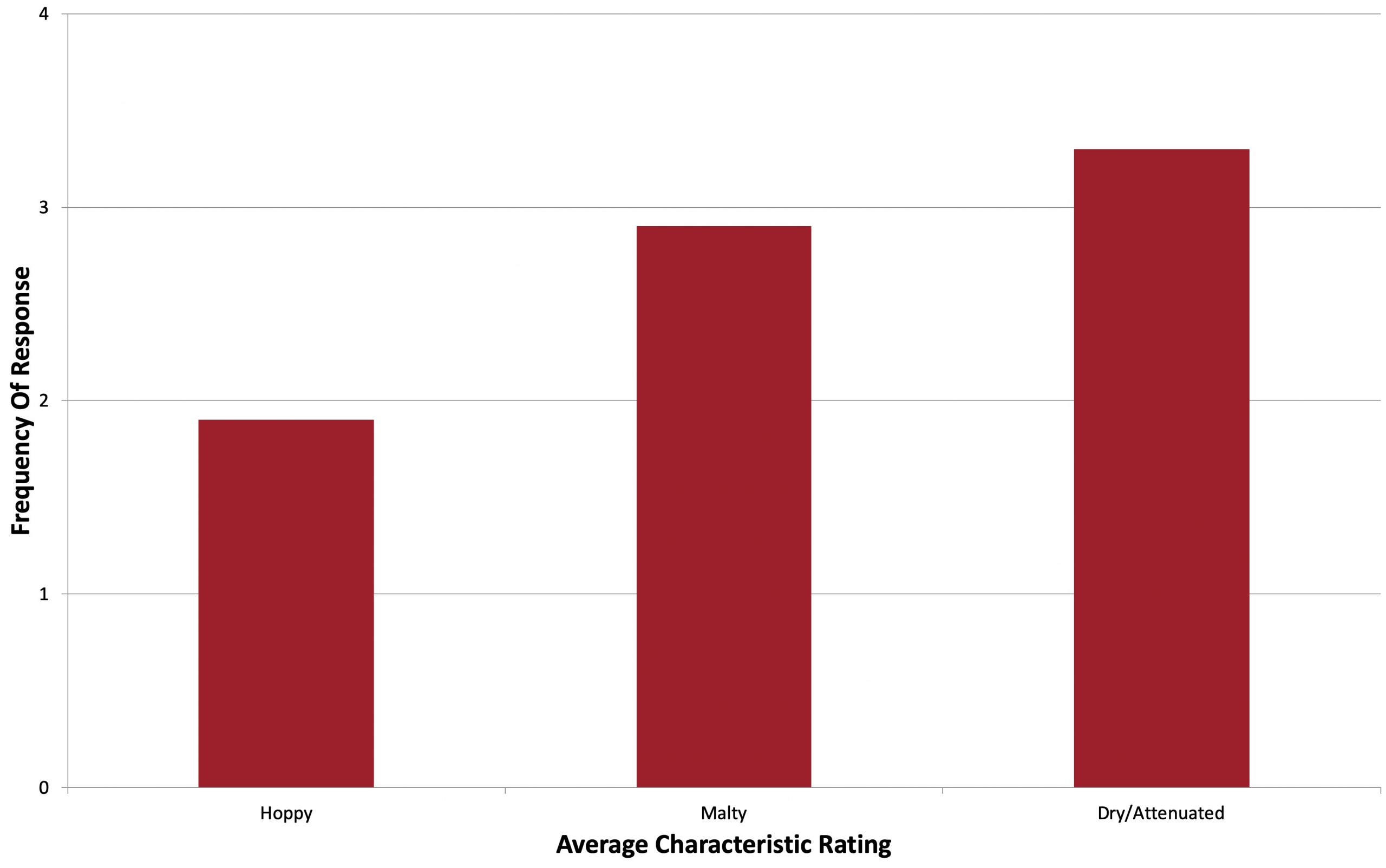

A total of 16 people of various levels of experience participated in this Short & Shoddy evaluation. Participants were informed of the specific beer style and provided the BJCP description prior to completing the survey. Tasters were then instructed to rate how hoppy, malty, and dry they perceived the beer to be on a 0-5 scale where a rating of 0 indicated “not at all” and 5 indicated “extremely.”

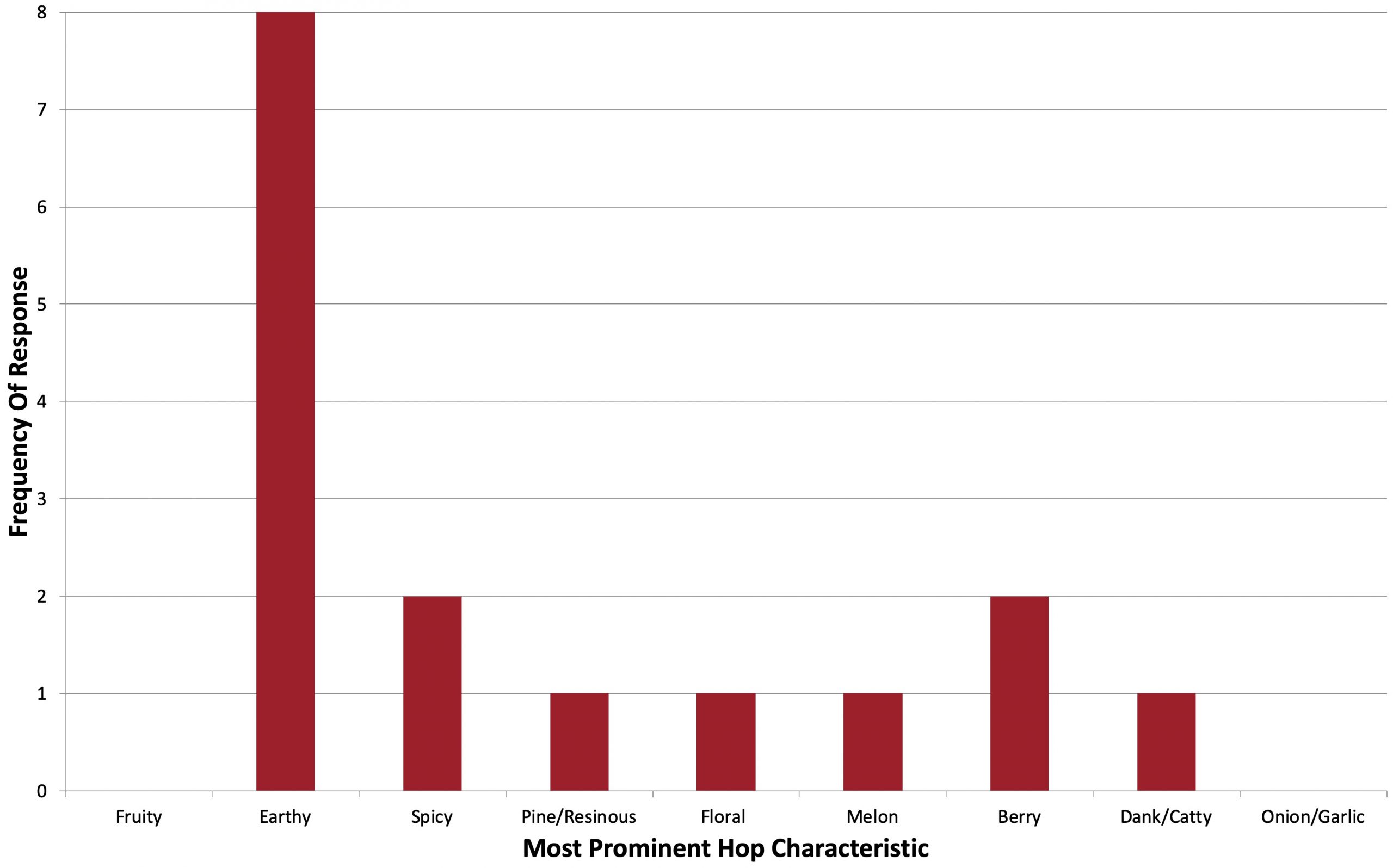

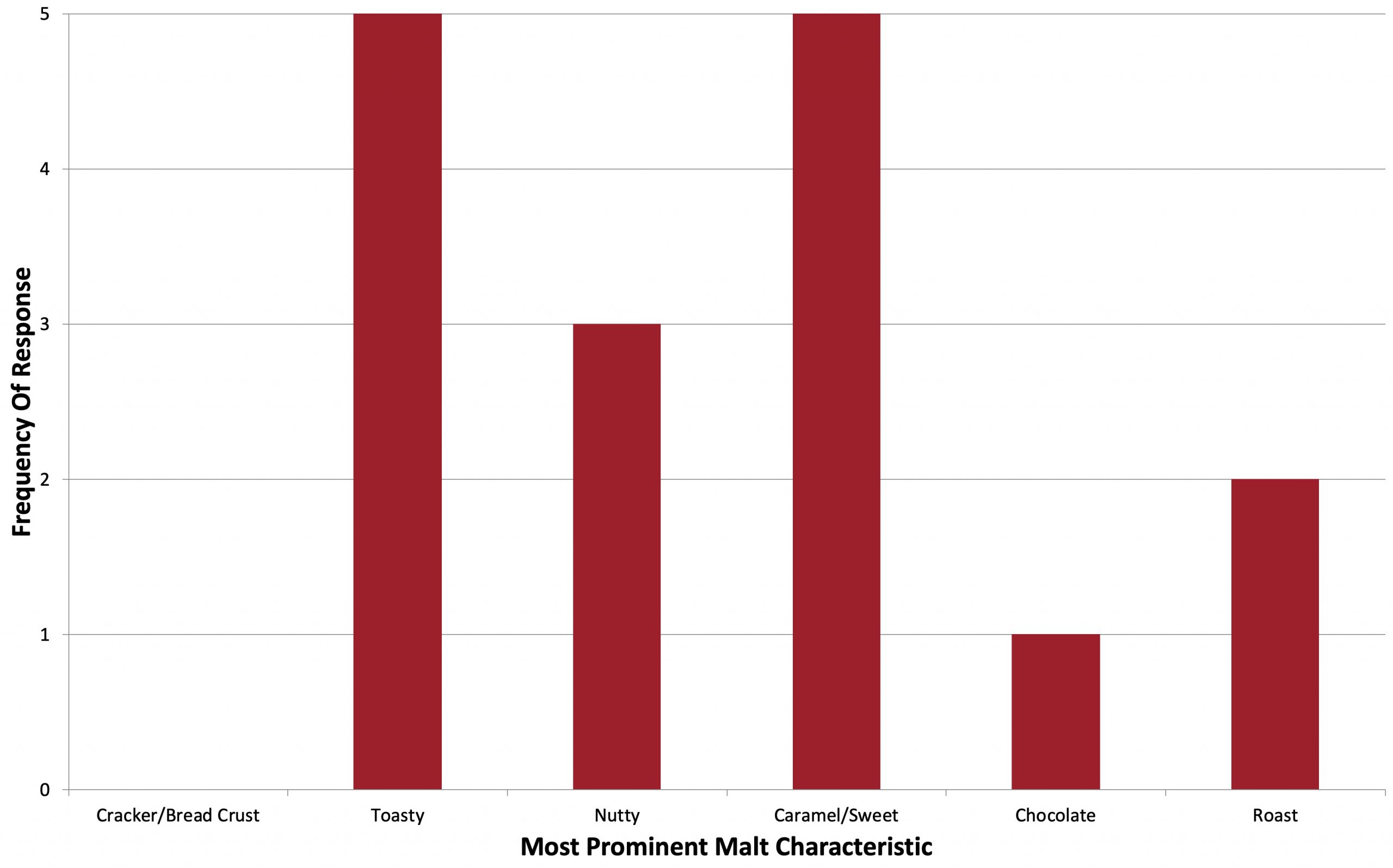

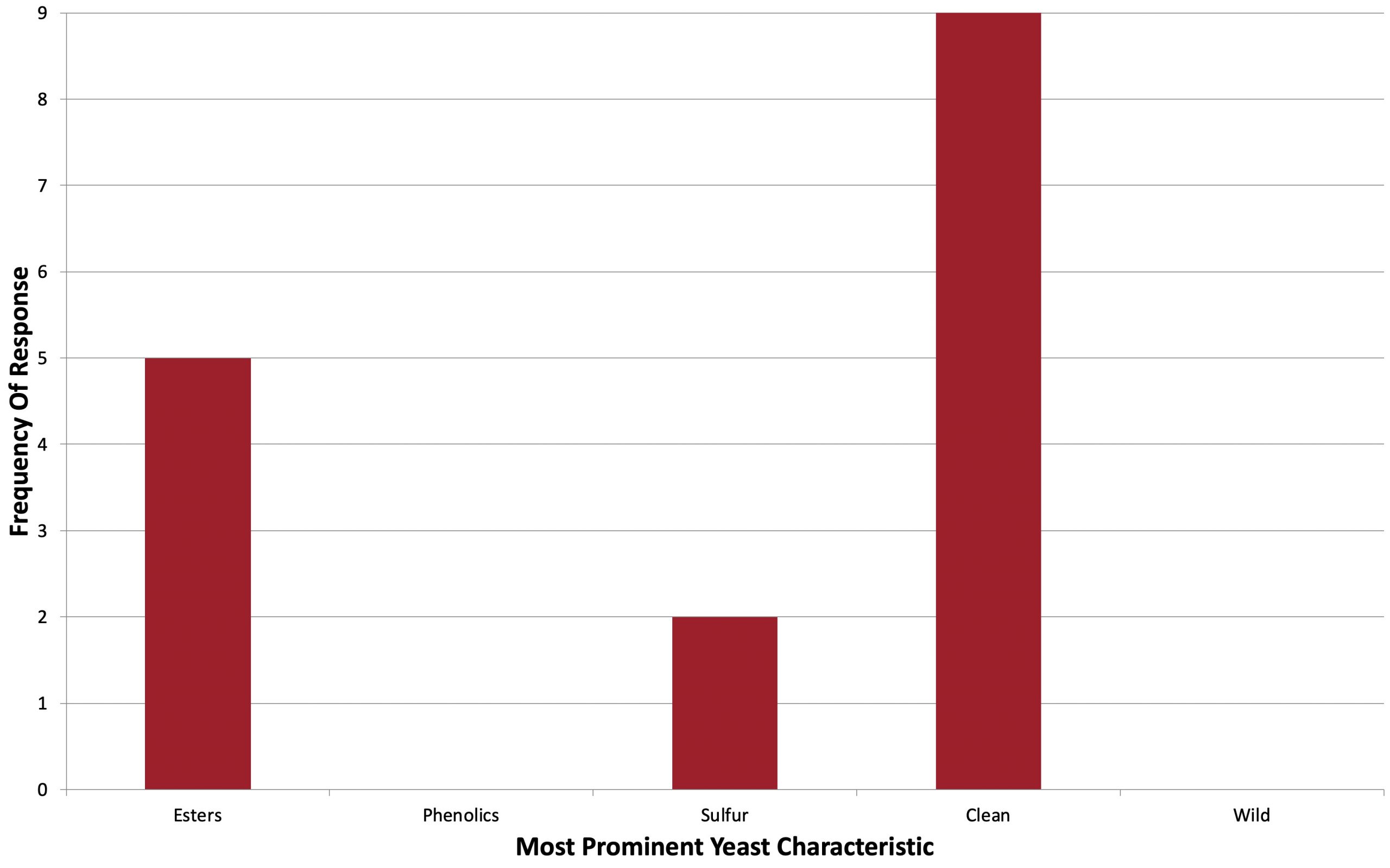

Tasters were provided a list of common hop, malt, and yeast characteristics then instructed to select from each the one they perceived as being most prominent in the beer.

Hop Characteristics

Malt Characteristics

Yeast Characteristics

Next, participants were asked to indicate whether or not they detected any off-flavors in the beer; those who did were provided a list of common off-flavors and instructed to select the one they perceived as being strongest. Only two tasters reported perceiving an off-flavor, one noting grassy and the other acetaldehyde.

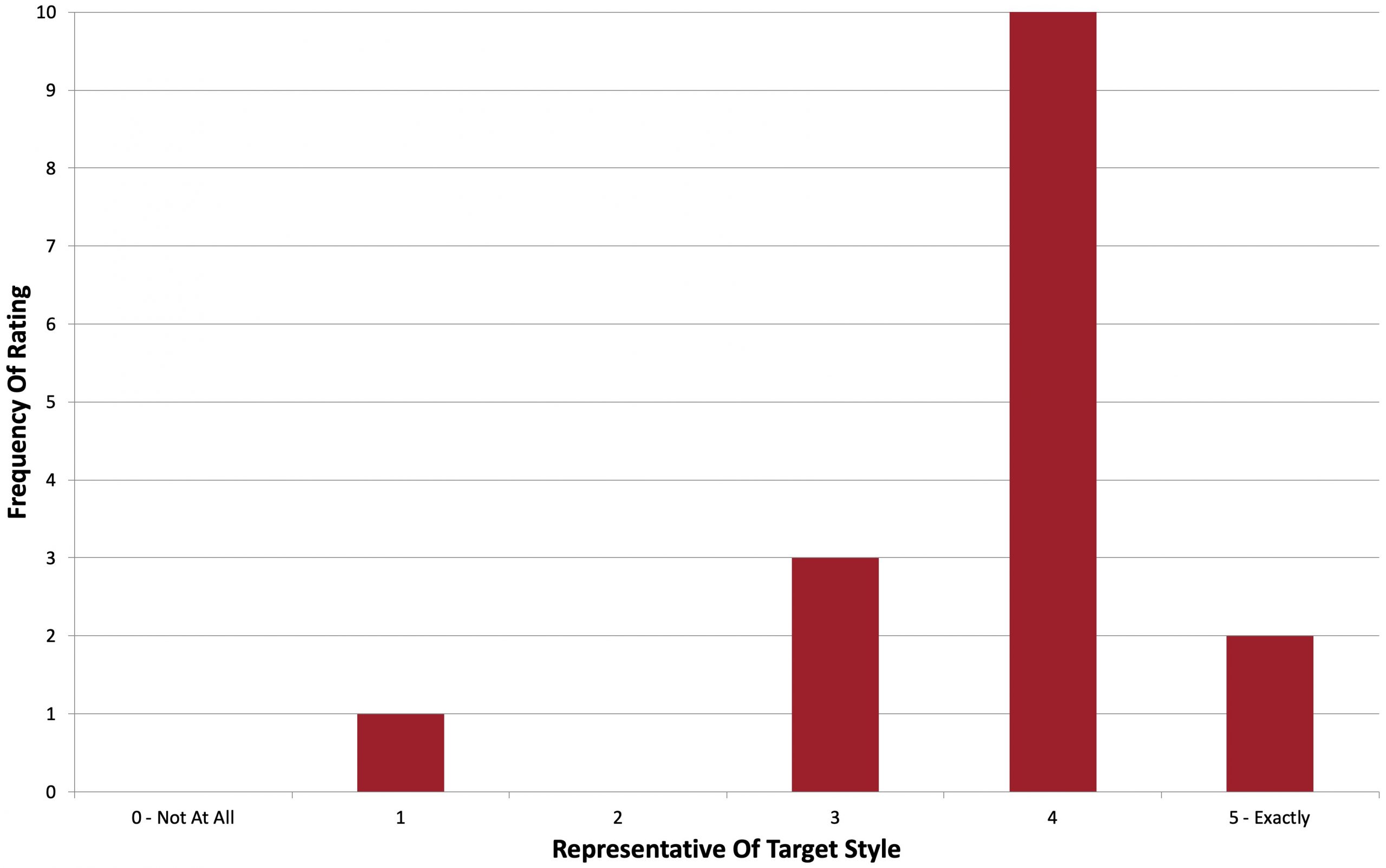

Tasters were then asked to rate how well the beer represented the intended style, based on the provided BJCP description, on a 0-5 scale where 0 meant “not at all” and 5 meant “exactly.”

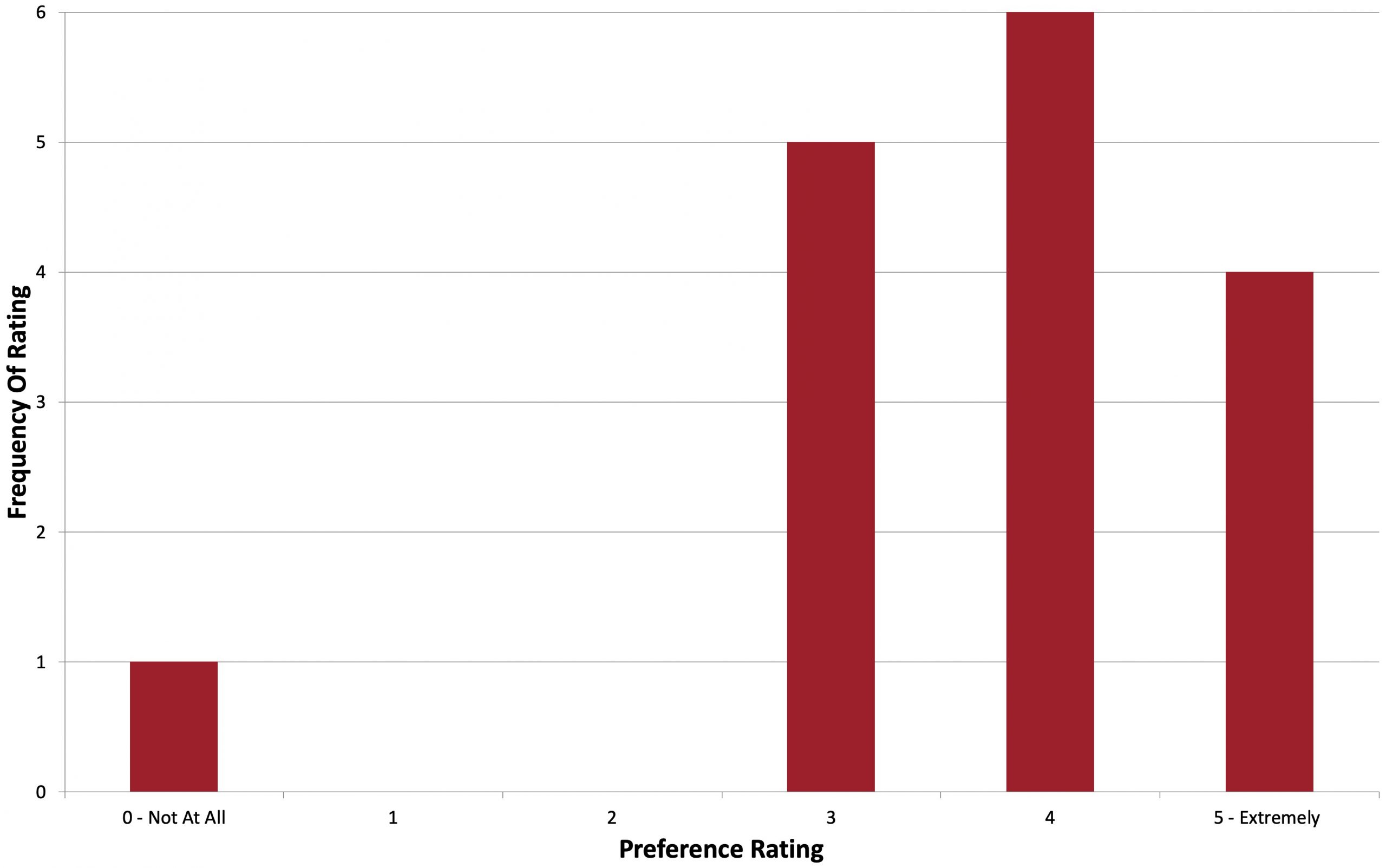

Finally, tasters were asked to rate how much they enjoyed the beer on a 0-5 scale where 0 indicated they hated it and 5 indicated they loved it.

My Impressions: Not only has it been awhile since I made an American Amber Ale, but I haven’t had a classic commercial example in some time as well. This batch hit the spot! Massive kudos to Ray for the recipe, which despite my bastardization of, produced what I felt was a really well-rounded beer with a nicely balanced flavor profile.

| CONCLUSION |

There’s no denying the fact the life on Earth is better because of the massive attention hops have received over the last decade. However, as the light shone brighter and brighter all things hoppy, it appeared to dim a bit on styles with less trendy feature characteristics, those that focus a bit more on malt flavors and balanced profiles. Styles like American Amber Ale, which at one point held a spot on nearly every brewery’s taplist.

There are a range of flavors one might expect from American Amber Ale, from biscuity and dry to fruity and sweet. In my opinion, the best examples are clean and dry, balancing toasty and caramel malt flavors with classic C-hop character that isn’t overshadowing. Based on the evaluations of tasters, this Short & Shoddy American Amber Ale got pretty close, particularly in terms of the malt profile. Curiously, a majority of tasters rated the most prominent hop character as being earthy, which while not out of place, made me wonder if perhaps the richness of the Mecca Grade Estate Malt may have had some influence. Regardless, preference ratings for this beer were overwhelmingly positive, in fact many of the tasters sought a refill after completing the evaluation.

Out of the 16 people who evaluated this beer, only 2 felt they perceived an off-flavor, one noting grassy and the other acetaldehyde. In post-survey chats, I learned the person who noted acetaldehyde detected what he described as a slight sharp, almost tart characteristic, which I simply couldn’t pick up even when focusing intently. I have noticed what I feel is a very pleasant hay-like characteristic when using Mecca Grade Estate Malts, which may explain the grassy flavor one taster noted.

All in all, I was rather pleased with the outcome of this Short & Shoddy American Amber Ale, particularly considering the brew day lasted just a couple hours. The beer was popular among all (but one) of my friends, and I thoroughly enjoyed having available a style of beer that hearkened back to my early days of drinking. I’ll absolutely be brewing this one up again in the future!

If you have thoughts about this Short & Shoddy brew, please feel free to share it in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

28 thoughts on “Short & Shoddy | American Amber Ale”

Woah woah woah your Christmas tree is already up?

We’ve got a party this weekend, and honestly, I’m not complaining.

Nicely done! It’s never too early for the Christmas tree. When’s the “Christmas vacation” viewing party?

Right after a thanksgiving dinner.

Dude no Xmas stuff until after Thanksgiving. Ha!

Dude, no gatekeeping holidays! 🍻

Sounds cool but don’t know what that means. I just put my easter stuff up so it’s all good

75ibus seems really high for an amber, no? I thought that was IPA range. I just brewed an amber yesterday (for the first time in years) and targeted 20ibu.. guess if that’s way off I’ll try a dry hop charge 🙂

I though the same thing and asked Ray, he said, “Trust me, it works.”

I am curious about your CO2 capture set up. How long does it take to empty the first corny keg? I just did this for the first time with my Spike CF – 15 and in about 2 hours it was empty so I hooked up another keg with sanitizer. Presumably if left connected pressure would build up

Yep, generally about 2ish hours after active fermentation starts. I just leave it connected until fermentation is almost done, disconnect and let the beer finished under pressure before cold crashing.

Any thoughts on the first bits of gas coming out of the fermentor being the air in the headspace of the fermentor?

With as vigorous as fermentation gets, I’d have to imagine over the 3-4 days its ripping along, most of the O2 is pushed out. If not, the residual is low enough to have not caused any issues for me.

Was wondering how the CO2 capture works as well! Looking to do something like this

When converting a normal 60 minute boil recipe to a short and shoddy 25 minute boil, do you adjust the amount and timing of additions such as hops? I assume the later additions don’t matter but if the original recipe calls for a 1 oz addition for 60 minutes, would you bump up the amount a little at 25 minutes to get the IBUs you want out of it?

I adjust the initial hop addition to match the intended IBU of a 60 minute addition. Presumably more hop character, but I haven’t really noticed that as being the case.

Damn it Marshall! There you guys go again brewing a style I haven’t had in a while. Now I have to change my brewing schedule to accommodate another beer (joking of course).

All kidding aside, its nice to see a classic get some love. Especially in the world of the IPA craze. Also, a note on the earthy hop comments. I can’t remember seeing or reading a recipe in the last 2-3 years that used such a large 15 minute hop addition with no other whirlpool or dry hops added. I’m guessing what tasters were experiencing was more of the hydrocarbon fractions of the hops, which they are not used to tasting these days (yes, I read Scott Janish’s new book). I think this is mostly due to brewers moving most if not all hop additions to the whirlpool and dry hop these days, which seems to push the fruit/citrus flavors. If this same recipe had a whirlpool or dry hop addition, I would be curious to see if the earthy score would go down while raising one or two of the other hop descriptor scores? Thoughts?

Very interesting idea, thanks Will. Now go brew a tasty American Amber Ale!

I love these short and shoddys but I just can’t bring myself to do one. I will often screw up a beer (fuck up the hop additions, mis-measure something, mash too high/low) and, despite all that the beer tastes perfectly fine. However, I can’t get it out of my mind that I screwed up the beer and swear to the gods I can taste the screw-up. As a result, the enjoyment of my beer suffers a smidgen.

It’s almost like a phobia — not quite rational but I can’t help it. You know what I mean here? Do any of you have that issue?

I’d call that bias. “I know I did these things I’ve read should cause issues, and now I taste the issues.”

I have question regarding mash pH. Why did you opt for 5.3.? I remember reading in Palmer’s How To brew the monograph where he suggest higher ph for brown beers.

i once brewed a similar beer with low pH, and felt a bit sharp, not fluffy. Planning on brewing again with 5.6(Room temp), ang look for differences

I didn’t opt for 5.3, that just happened to be where it landed. That said, based on my experiences and our xBmts, I’m not sure pH is as important as mineral composition.

Marshall: Have you considered closing the loop on your transfer? You could run a line from your keg’s gas to your fermenter gas post. As the liquid displaces your gas in the keg, it forces gas back into your fermenter which then pushes liquid into keg. It would close your process and prevent you from having to use tank CO2 to transfer. Just a thought.

You’d have to have enough pressure in the first keg to push the beer in the fermenter out. Pretty sure that’d be tough to do.

You could hit the keg with a quick 10 psi charge before connecting. I do it with my Anvil fermenters and it works like a charm. Would post a pic but can’t.

Ahh, interesting idea!

I could not get my gravity down below 1.025 any ideas what might have happened?

I’ve heard of this happening from friends twice, one of them realized his thermometer was uncalibrated and thus he was mashing much warmer than expected, while the other was certain he pitched yeast that puttered out due to being old.