Author: Marshall Schott

IPA is an assertive style in many respects, possessing relatively high levels of bitterness, hop character, and alcohol, which can hinder ample consumption. While American Pale Ale offers drinkers a generally more restrained option, the style as classically interpreted tends toward more of a balanced malt and hop profile, which can leave a hop-heads wanting for more.

Purportedly coined by Full Sail Brewery, the term session is commonly used to describe beers of lower ABV that can be guzzled by the growler full. Typically reserved for styles that naturally tend toward the lower end of the alcohol scale, there’s been increased interest in crafting beers of such humble potency that pack more of a hoppy punch than traditional Pale Ale.

Enter Session IPA, a non-style style with an arguably oxymoronic moniker that has caused quite the kerfuffle among those who care a bit too much. Too hoppy for an APA and not enough sauce to be an IPA, Session IPA is a sort of mental amalgamation of ideas thrust into a pint glass. With no formal section in the BJCP guidelines, Session IPA falls into the category of Specialty IPA and requires the brewer to specify the strength when entering one in a competition. The description matches that of American IPA with the exception of that ABV falling in the range of 3.0 – 5.0%.

A decidedly hoppy and bitter, moderately strong American pale ale, showcasing modern American or New World hop varieties. The balance is hop-forward, with a clean fermentation profile, dryish finish, and clean, supporting malt allowing a creative range of hop character to shine through.

A commonly cited problem when brewing Session IPA has to do with creating a beer that’s full-flavored and creates the organoleptic impression of a regular IPA without being watery or lifeless. Having developed a few hypotheses based past xBmt results, I was curious to see what might come of making such a beer using some not-so-traditional methods.

| BREWING THE BEER |

My thinking when designing this beer was influenced largely by past xBmts showing that beers with a higher FG aren’t necessarily more sweet than those that attenuate more, at least to an easily distinguishable degree. As such, I used more malt in this batch in hopes of retaining adequate body and flavor, while adjusting the mash temperature up to limit fermentability.

Short & Shoddy Session IPA

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 30 min | 44.9 IBUs | 6.3 SRM | 1.048 | 1.017 | 4.1 % |

| Actuals | 1.048 | 1.018 | 4.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta American-style Pale Malt (Mecca Grade) | 10 lbs | 81.63 |

| Vanora Vienna-style Malt (Mecca Grade) | 1.5 lbs | 12.24 |

| Metolius Munich-style Malt (Mecca Grade) | 12 oz | 6.12 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Horizon | 13 g | 30 min | First Wort | Pellet | 14.1 |

| Citra (2014) | 15 g | 10 min | Boil | Pellet | 13.8 |

| Comet (2015) | 15 g | 10 min | Boil | Pellet | 9.6 |

| Comet (2015) | 40 g | 2 min | Boil | Pellet | 9.6 |

| Cali Chinook (2018) | 30 g | 2 min | Boil | Pellet | 11 |

| Citra (2014) | 30 g | 2 min | Boil | Pellet | 13.8 |

| Comet (2015) | 25 g | 5 days | Dry Hop | Pellet | 9.6 |

| Cali Chinook (2018) | 20 g | 5 days | Dry Hop | Pellet | 11 |

| Citra (2014) | 20 g | 5 days | Dry Hop | Pellet | 13.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Tartan (A31) | Imperial Yeast | 73% | 65°F - 70°F |

Notes

| Water Profile: Fresno Tap + a palm full of gypsum |

Download

| Download this recipe's BeerXML file |

My brew day began with the collection of water, which I ran through a cheap carbon filter.

While the water was flowing, I poured a small mound of gypsum into the palm of my hand then tossed it into the liquor. No other adjustments were made.

I lit the flame under the kettle to begin heating the full volume of brewing liquor.

As the water warmed, I weighed out and milled the grains for this batch.

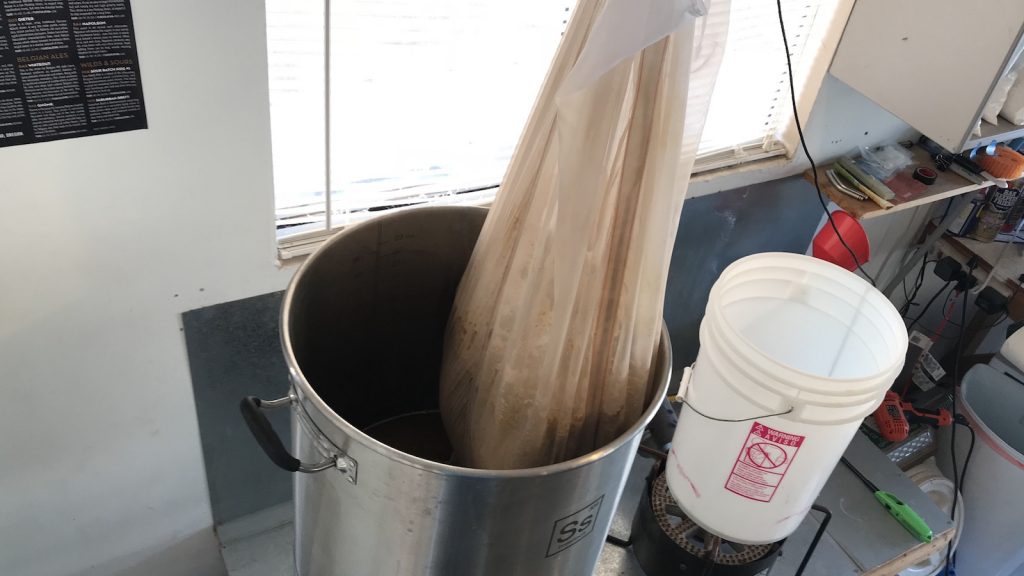

It took a little bit longer to heat the strike water due to the fact I would be mashing at a much warmer temperature than usual. At 35 minutes from water collection, I dropped the bag of grains into the hot water, gave it a good stir, then made sure the mash was where I planned on it being.

After a zippy 20 minute rest, I removed the grain bag and let it drain while the wort was being heated.

I then proceeded to weigh out the hops, most of which I’d recently discovered sitting in the back of my freezer, the Citra having somehow lost it’s vacuum since I last used it over a year prior.

The wort was boiled for 30 minutes with hops added per the recipe.

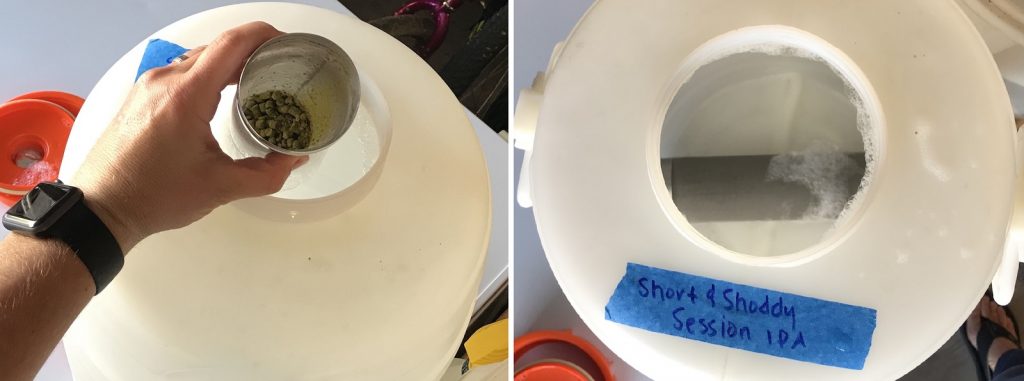

During the boil, I poured the rather hefty dry hop addition into a stainless mesh sleeve and dropped it directly into the empty fermentation vessel.

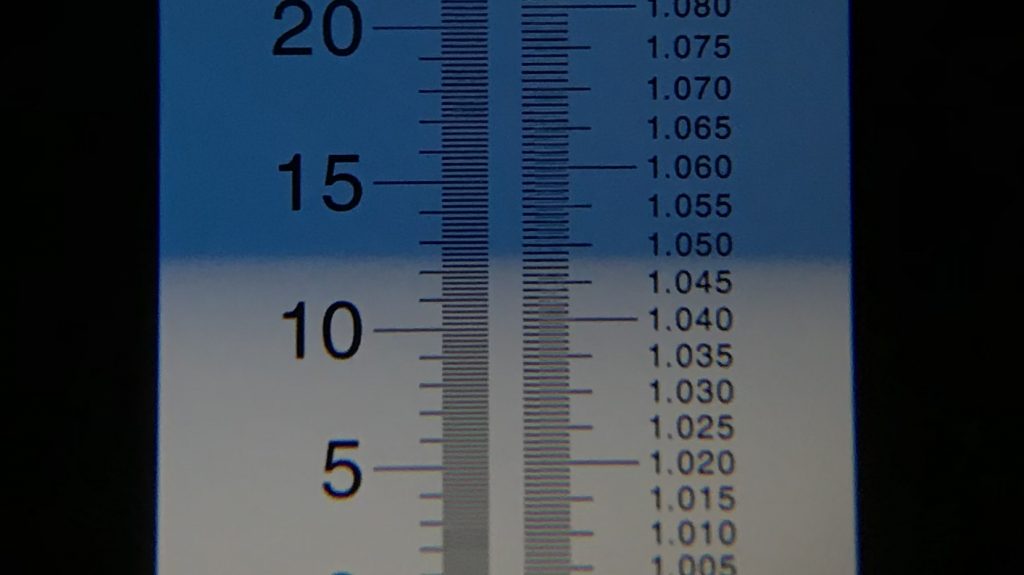

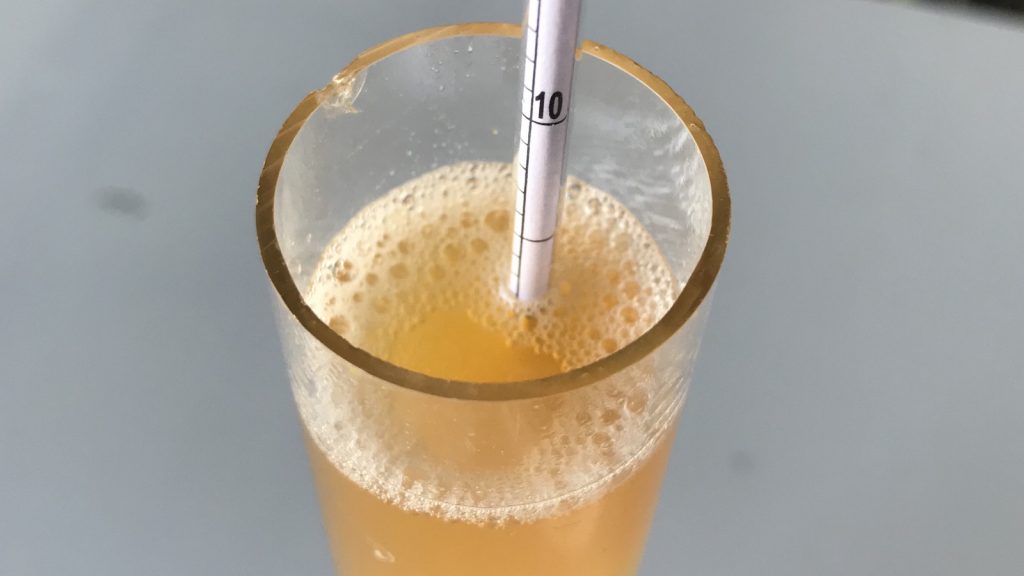

At the end of the short boil, I quickly chilled the wort is my immersion chiller and took a refractometer reading showing it was smack on where I hoped it would be.

I then racked 5.5 gallons of wort to a plastic fermentor that held the dry hop charge.

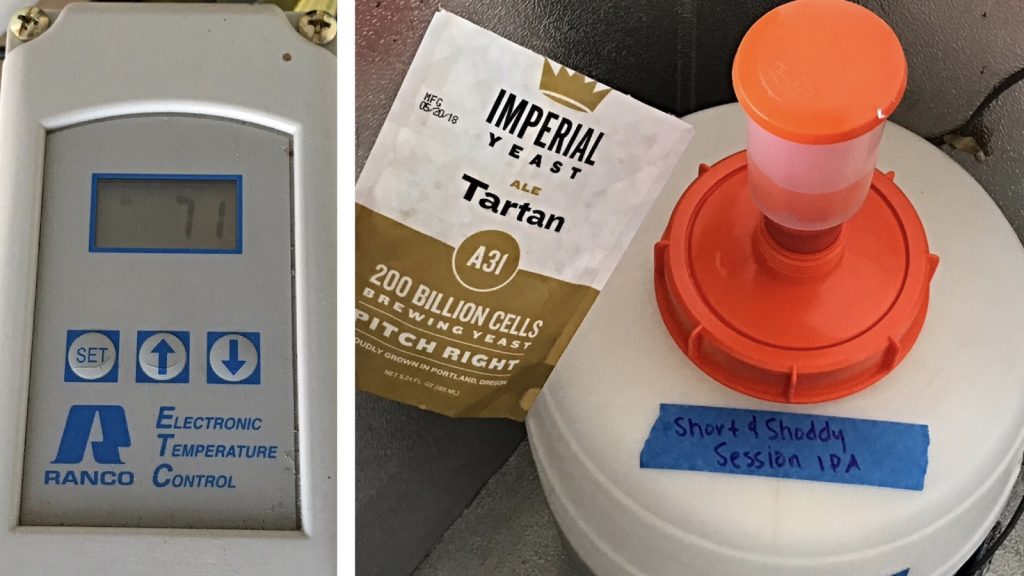

The filled fermentor was placed in my chamber controlled to 66°F/19°C. The wort was sitting at 71°F/22°C, warmer than I might usually pitch the yeast, but hey… in went a single pouch of Imperial Yeast A31 Tartan. This was exactly 2 hours 15 minutes after I started brewing.

I checked on the beer 8 hours later and didn’t notice any activity, something I attribute to direct pitching a pouch of yeast that was over 5 months old. While slightly concerned at first, my worries were quelled when I observed a bubbling airlock the following morning, less than 24 hours post-pitch. After 6 days of fermentation, I noticed activity was completely absent and took a hydrometer measurement showing my high mash temperature plan had worked– the beer finished at 1.018 FG.

After swapping out the airlock with a CO2 filled BrüLoonLock, I reduced the temperature in my chamber to 34°F/1°C for cold crashing.

Later that evening, once the beer had dropped below 50°F/10°C, I added some gelatin in hopes of clearing the beer up. I let that sit for another 20 hours before racking the beer to a sanitized keg that had been purged with CO2. The filled keg was placed in my cool keezer and hit with 50 psi of CO2 for 14 hours of burst carbonation before I reduced the gas to serving pressure. After 4 more days of cold conditioning, the beer was ready to serve to serve to participants.

| RESULTS |

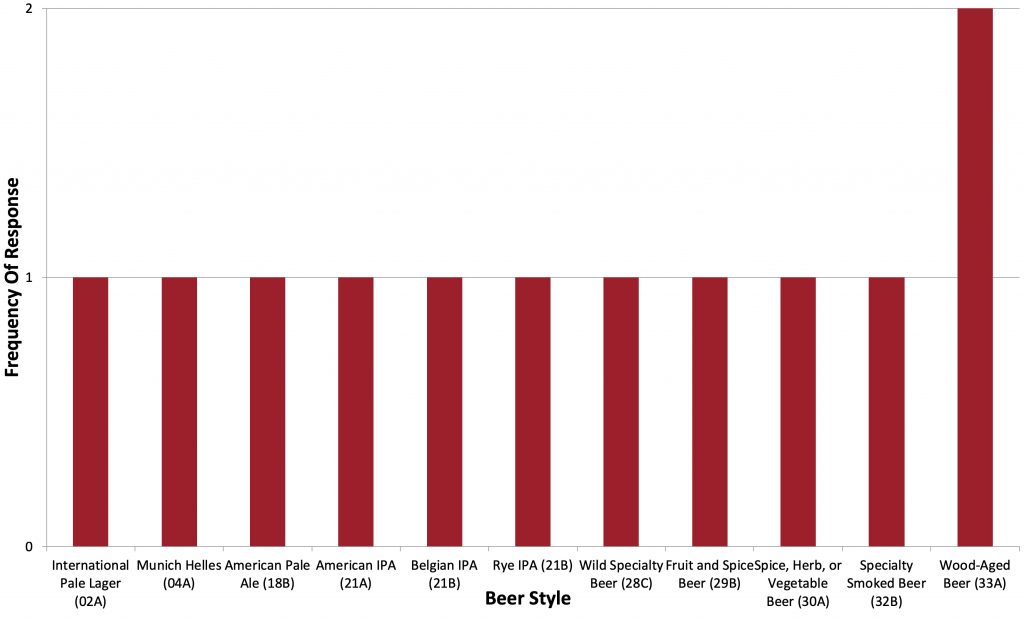

A total of 12 people of various levels of experience participated in this Short & Shoddy evaluation. Participants were first asked to identify the style they believed the beer to be based on their perception.

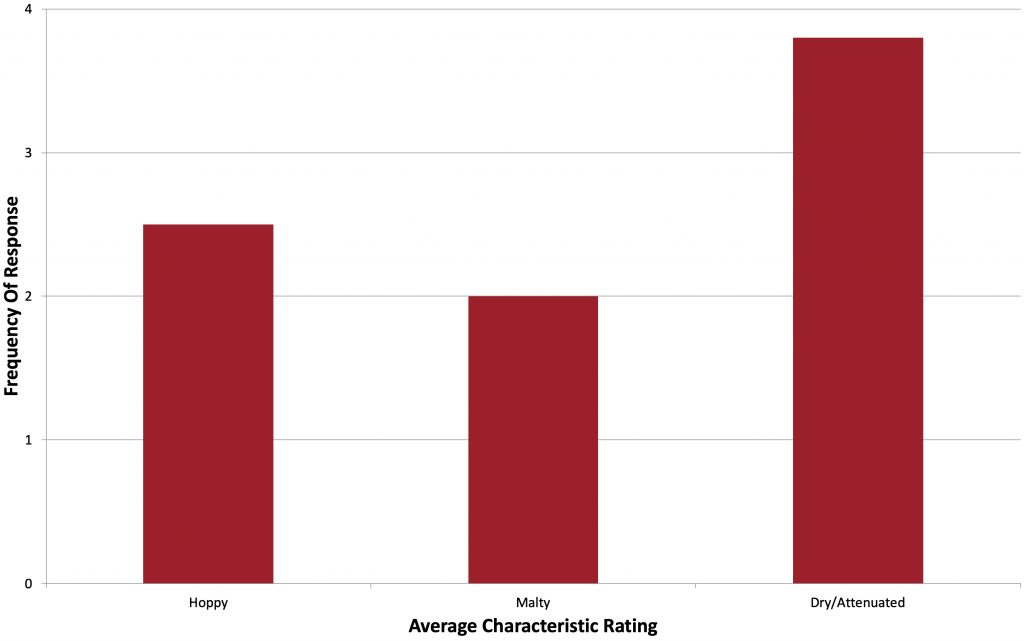

Tasters were then instructed to rate how hoppy, malty, and dry they perceived the beer to be on a 0-5 scale where a rating of 0 indicated “not at all” and 5 indicated “extremely;” these ratings were then averaged.

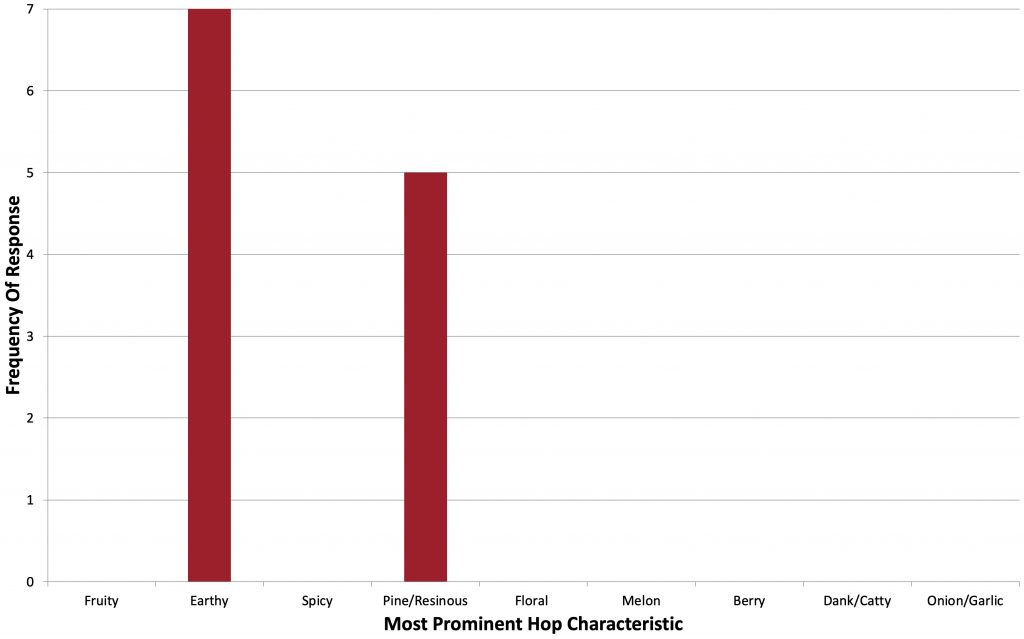

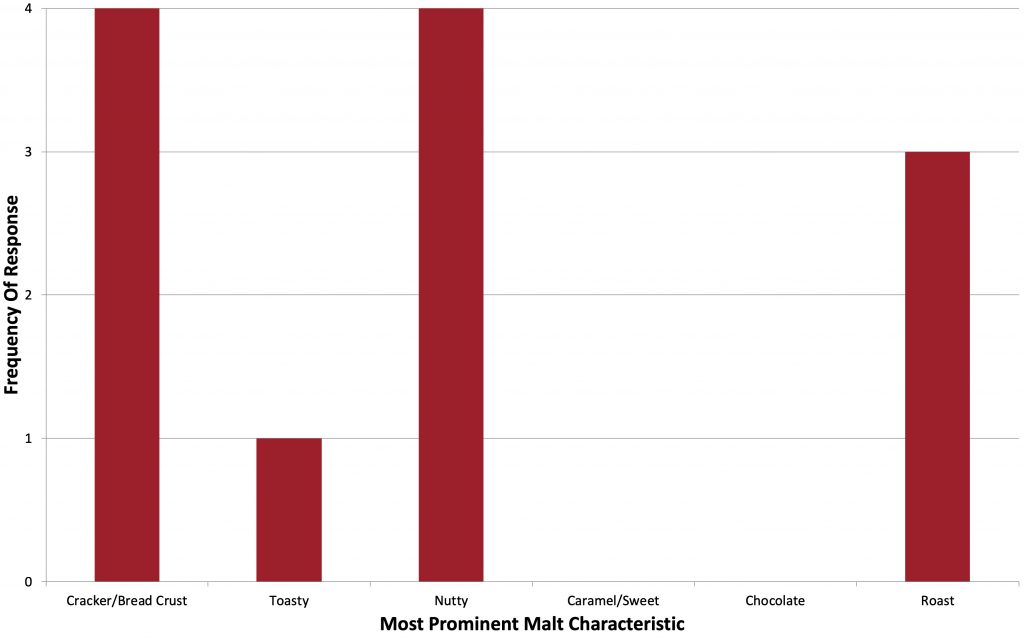

Tasters were provided a list of common hop, malt, and yeast characteristics then instructed to select from each the one they perceived as being strongest in the beer.

Hop Characteristics

Malt Characteristics

Yeast Characteristics

Next, participants were asked to indicate whether or not they detected any off-flavors in the beer; those who did were provided a list of common off-flavors and instructed to select the one they perceived as being strongest. Of the 6 people who noticed off-flavors, 2 identified astringent and 1 each noted metallic, acetaldehyde, diacetyl, and alcoholic.

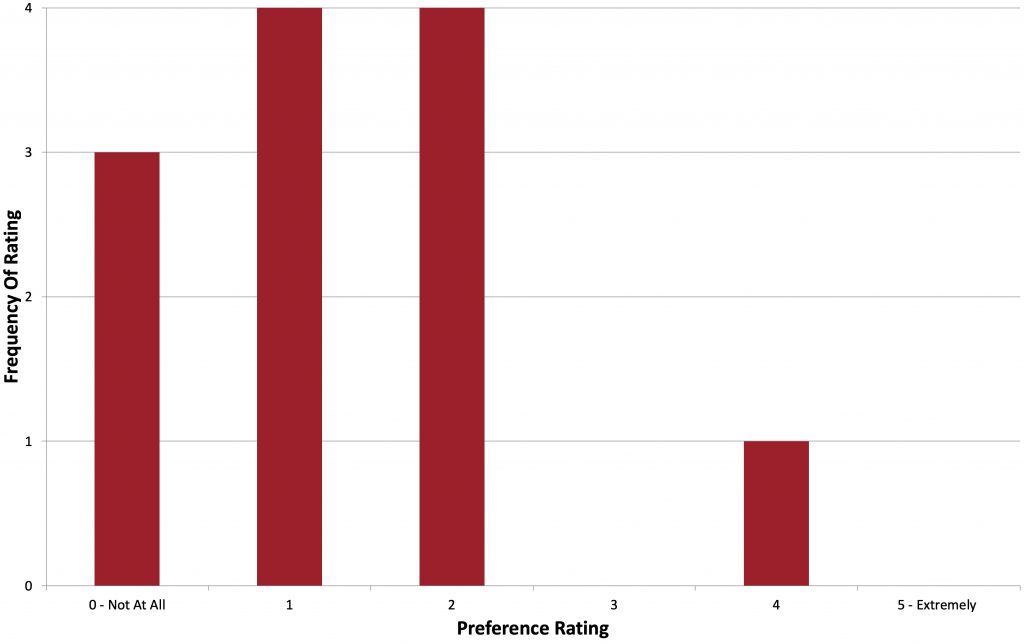

Tasters were then asked to rate how much they enjoyed the beer on a 0-5 scale where 0 indicated they hated it and 5 indicated they loved it.

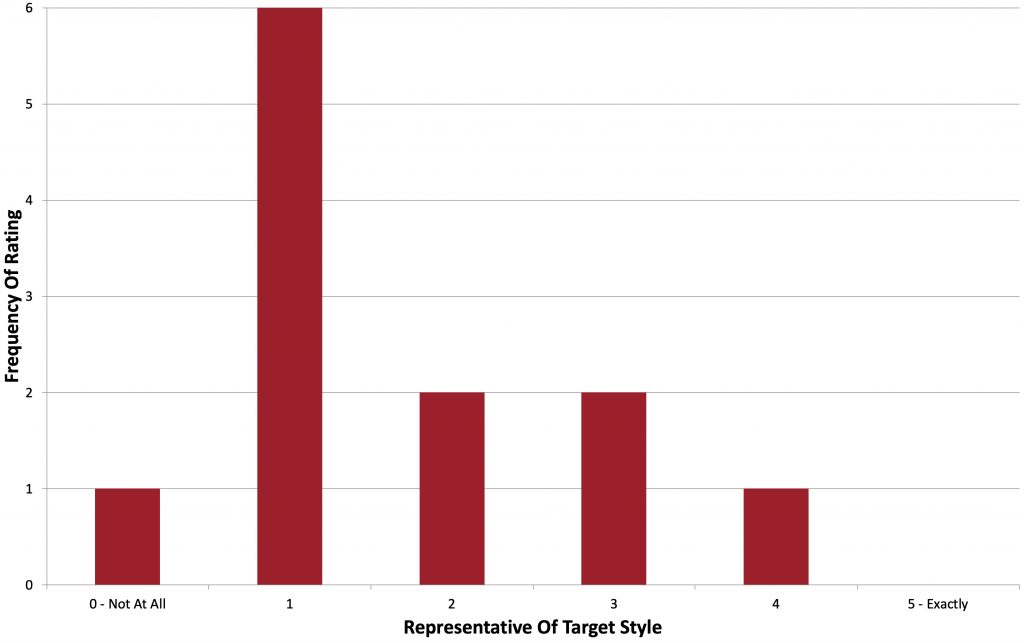

Finally, the beer style was revealed to participants and they were asked to rate how representative it was on a 0-5 scale where 0 meant “not at all” and 5 meant “exactly.”

My Impressions: Focused almost entirely on malt flavor and mouthfeel, I was rather impressed upon my first sampling of this beer prior to packaging. I’ve found most beers improve once carbonated and cold conditioned for a bit, but I was pleased to have discovered the beer wasn’t watery or completely pallid. I started to get a little worried when tasting the beer after a day of burst carbonation, the fizz seemed to bring something out that was rather… unique. When it came time to collect data a few days later, I finally accepted something had gone awry and that this beer just wasn’t good, to the point I felt terrible asking people to evaluate it, hence the lower than normal number of participants. It wasn’t laziness, it was a gesture of good will.

| CONCLUSION |

Session IPA is supposed to mirror all of the characteristics of a good IPA but with less alcohol, making it all the more crushable. A common method for accomplishing this involves using a smaller amount of grain, though as many brewers have experienced, this can lead to lacking flavor and body. To counter this, I relied on the results of past xBmts showing a higher FG doesn’t necessarily correspond to more perceived sweetness and mashed my Short & Shoddy version of this style a bit warmer than usual, allowing me to use more flavorful malt. And it worked, the beer finished with a higher FG and lower ABV without being cloying.

Unfortunately, any good that was present in this Session IPA was overshadowed by the sharp bitterness that lingered way too long on the palate and general absence of the fruity hop character one might expect considering the varieties and amounts used. Rather, the beer was strikingly earthy and woody with an odd whisper of smoke that was completely out of place for the style. Given its similarity in taste to a beer I made using old and poorly stored Simcoe hops awhile back, I’m compelled to think the fact I used mostly old hops that I found sitting in the back of my freezer seemed a likely contributor, though I wasn’t convinced that was sole culprit.

A few years ago, I recall someone telling me they get a slight hint of smoke in beers they ferment with the McEwan strain, which Imperial Yeast’s A31 Tartan is said to be sourced from. While I’ve not used this particular yeast enough to form an opinion for myself, I couldn’t help but wonder if perhaps this is where the smoky character in my Session IPA came form. Another idea that crossed my mind is that something about adding the dry hop addition yeast pitch screwed with the character of the finished beer. I’ve done this a few times with success, but it seems at least plausible my use of this method was at play in the shoddy results.

In the end, this beer was a complete and utter failure, tasting nothing at all like the beer I envisioned when designing the recipe. I considered the possibility of a contamination, but based on the fact the FG hadn’t changed at all even after 3 weeks in the keg, I really don’t think that was it. Oxidation comes to mind as well, but that seems unlikely seeing as I took the effort to limit oxygen exposure during cold crashing and packaging. Accurately identifying characteristics of a beer with such strong overtones can be difficult, but I’m pretty sure this Session IPA was free of any of the feared by-products of the Short & Shoddy process. No, it just tasted like old hops.

Brewing a shitty beer is a major bummer for most people, but I tend to view it as a part of the learning process, even when it’s bad enough to demand dumping down the drain, as this one did. In addition to being quite humbling, this experience motivated me, not only to rid my freezer of 3+ year old hops, but to brew a Session IPA using Short & Shoddy methods that people actually enjoy drinking.

If you have thoughts about this Short & Shoddy brew, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

38 thoughts on “Short & Shoddy | Session IPA”

you gotta just dump the bad or mediocre ones! hops have a way of piling up in the freezer over time dont they?!

What is the purpose of the balloon?

Keep oxygen away from the beer.

They are filling the balloon with C02 from fermentation. The idea behind is when you cold crash you are not drawing in oxygen but C02 from fermentation.

I had a similar experience with old hops – a technically good APA which just tasted plain odd. Nevertheless I have an APA in the fermenter right now, the sole purpose of which was to use up a freezer full of hops. We will see how that one turns out – none of the hops were older than HomeBrewCon this time!

I’ve heard and also read in Jennifer Talley’s book that favoring calcium chloride in session beers over gypsum is preferred regardless of style. Reason being sulfates reportedly thin out the mouth feel of the finished beer especially in the presence of carbonation. Doesn’t seem to the issue with this beer but maybe an xbrmt between session IPA’s one 2:1 chloride to sulfate and the other 2:1 sulfate to chloride keeping the alcohol under 5%. Seems like it would be easy to test and I don’t remember this being tested on a session beer before. I admit I was too lazy to go back and check though. Good xbrmt even if the beer came out bad. We often learn more from our failure than our success. Cheers!

I’ll second this suggestion, I’ve found both my dry Irish stout and my session IPA to be more enjoyable and “balanced” , with a bit more CaCl. Your Mileage May Vary, but I’d also love to see a mineral addition Xbrmt done on a session beer.

+1 on the Talley suggestion. I haven’t tried this in a short and shoddy manner, but not sure any of my experiences would allow an accelerated brewery. I’ve had good success with and IBU/SG of about 1, ~15% carapils for dextrine, mash at ~155F and a 5:1 Chloride to sulfate ratio (count to standard IPA) to emphasize the lower amounts of malt in this style.

I was also wondering if the “biotransformation” of the older hops in the dry hop (during active fermentation) is giving some of the odd flavors.

Sorry for the dumper, but thanks for taking one for the team and sharing your experiences! I always appreciate you passing on your knowledge.

cheers

With a 5:1 chloride to sulfate ratio, do you ever get a mineral taste in the finished beer? What would be your ppm for the chloride? Just curious?

Not that i’ve noticed. My well water is really hard and it does get a very mineral taste if I use that straight (good for imperial stouts – though). For lighter beers, I cut my water with RO (50% or more – 90% for Czech Pils) and then build back. For this recipe, I shoot for about 100ppm Ca, 100ppm Cl and ~20 ppm S. So, not super high, but starting from lower values.

I really appreciate you publishing your results when when they didn’t match your expectations.

This. Being willing to post something that made you say “hmm” instead of “Aha!” is why I’ve been coming here for years.

I think perhaps you had too many variables. If you were chasing the illusionary session IPA, then maybe hammer out the product using tried and true techniques, not s&s. Next you used old hops. Remember your Simcoe experience? Crushable=fresh. Then you used a non-familiar yeast and started it warm. This batch was destined for the drain, but still a learning experience.

I’ve made a couple american IPAs with Scottish Ale strains. They had a subtle smokey flavour. It wasn’t unpleasant, but I wouldn’t do it again.

Dryhopping with poorly stored, 4-year-old hops eh? 😉

Thanks for sharing Marshall. Avoid old hops is my take away. Was wondering if using a more traditional yeast would have made a difference.

At first, I thought perhaps the rumors I’d heard about the McEwan’s strain were true and that it was responsible for the odd flavor. But after numerous samples, I’m pretty certain it was the old hops, all of which were relatively high oil and alpha varieties. This experience combined with past experiences has convinced me to use fresh hops all the time for hoppy Pale Ale and IPA.

I believe that this is absolutely a result of old oxidized hops. I recently brewed an IPA using a massive dose of old hops (they were incredibly cheap for a reason) and found the initial sampling’s quite tasty but it turned into an awful stale astringent bitter bomb within a couple days of being in the keg, exactly as you have described. Although it’s a huge bummer brewing a dumper, I’m relieved to see that you experienced the same issue I had which somewhat validates my suspicions on what went wrong with my bad batch.

Yeah, it tasted like other beers I’ve made with old oxidized hops. Blegh!

Was the color/smell of the hops unusual, they look a bit powdered (did you suspect they were bad before using them is what I’m getting at, or did they appear fine?) I just dry hopped with the bottom of a bag that was powdered out a bit, smelled fine, hopefully they were still good.

They looked okay, smelled a little… old :-/

I think if they smell fine, you should be good – at least for avoiding the isovaleric acid flavor. I brewed with some Huell Melon that got flagged and cracked open at the border, held for 5 days at mid summer temps. When I got them I thought maybe I smelled a bit of cheesyness… I had wort boiling so I just went ahead. Beer turned out gross, had hint of old socks / cheese…

Given the perception of Phenols in the survey my suspicion would be residual Belle Saison from fermenting hard cider in that fermenter. There may have been a few cells that didn’t get cleaned & the long lag time gave them a chance take hold to affect the flavor. In my experience phenols can seem smoky & they can make hops seem harsh. Just my guess from having similar experiences on a few batches after a Saison I did with belle….. Good luck!

I honestly don’t think it was phenols, at least I didn’t perceive the beer as being phenolic. Rather, I think the blend of beta acid bitterness and old oxidized hop flavor created a very odd character that some felt was closest to phenolic given the options. I’ve only used this fermentor for cider once, it was awhile ago, and I’ve since made numerous tasty beers in it.

Thank you for posting your failures along with your successes! It would have been easy to rationalize this was just due to old hops or a poorly designed recipe/yeast choice (which likely was the problem) and not representative of S&S and not post it. Thanks for doing what you do. Cheers!

I agree. It would’ve been easy to not post this xbrmt because the beer didn’t turn out well. Thanks for sharing!

Not to be a turd in the punchbowl but the descriptors are dead nuts on to a contamination. Now you tasted it and I obviously didn’t. But phenolic/smoky, with a dry/attenuated perception and some thinking it’s wood aged (tannic…possibly) all point to an infection. Some people are really super tasters of phenols (or diacetyl, btw) while others don’t perceive it the same. It’s possible that the infection is just starting and that you’d see the drop in FG over time, or via a forced ferment test. If you haven’t sewered it, this might give your answer.

I obviously can’t say that it’s NOT old hops, but there are many points in the process where you could have introduced wild yeasts or other contaminants. Some wild yeasts don’t even really produce alcohol as final product though I’m unsure of how it would impact FG.

As one data point (and the plural of anecdote isn’t data) I’ve brewed with 4 year old leaf hops that were not kept under vacuum, but were in a freezer. The flavors were a bit muted (less bitter and less aroma) but they still tasted like hops. Obviously different varietals differ.

Y’all know what you’re doing and I’m not trying to be critical. Just that sometimes the answer is directly in front of us and we don’t see it…

FWIW, my last batch was infected and tasted just like you described. Third one sewered in 20 years. boo.

Marc

In addition to having tasted many contaminated batches of beer as well as this particular beer plenty of times, I also spoke with the tasters after they completed the survey and not a single one felt the issue was contamination. Could it have been? For sure! But in my experience, Contaminated beers rather quickly worsen over time and will continue to lower in FG. Out of curiosity, I took a hydrometer measurement 9 days after kegging the beer (de-carbonated and warmed), it was exactly the same as prior to kegging.

Again, I’m not trying to be defensive, and I have zero issues admitting when a batch is contaminated– shit happens. However, this beer tasted exactly like other beers I’ve had/made that were hit with a lot of old oxidized hops.

Should flatten it and put it on some funky schtuff. 😀 😀

Befriend a distiller and make some beer whiskey!

For what little it’s worth, Full Sail uses the term session to refer to a session of surfing (so I’ve been told) and the British have used the term “session” in relation to low alcohol beers for a LOOOOOONG time

+1 I live near Full Sail and doubt they would claim coining the term session or session ale. However I am pretty sure they have a copy right for Session Lager and what has turned into a line of Session beers.

Before think about the old hops used, I have two other things that come to my mind.

The mash was only 20 minutes at 165F. Have you checked for residual

starch that hasn’t been converted yet by the enzymes?

Secondly, does boiling for only 30 minutes get rid of all the DMS?

I could imagine that a starchy taste and a sweet corn flavor (DMS) have covered the hops and malt flavor and aroma. That beer must have been awful!

I didn’t perform a conversion test, but I can say with confidence the bad flavor wasn’t starchy or corny, but rather the beer was bitter with an oxidized hop flavor.

OK, thanks for the answer!

Actually, after my comment yesterday, I discovered your experiments with short mashes and short boil times, and they look very promising! I’ll have to try this out on my next brew day – or brew evening if everything is so quick! 🙂

Keep up the excellent work!

Not convinced its the yeast, I live in Edinburgh and for years before their demise the Mcewans range were the most widely available for obvious reasons and I don’t ever recall a smokiness to their beers.

Yeah, I don’t think it’s the yeast either.

Do you prefer the Spiedel fermenter over the SS Brewbucket?

I don’t, but the Speidel is a great option that won’t break the bank. My biggest issue with it is that the plastic can be scratched, and over time it will start to retain beer aromas, which could possibly impact subsequent beers (xBmt planned). The stainless is essentially indestructible and super easy to clean, but the conical bottom makes kegging a bit less of a hassle.