Author: Jake Huolihan

I recently switched from the batch sparge brewing method where I used a converted cooler MLT with a stainless braided hose to an electric Brew In A Bag (eBIAB) setup, which caused me for the first time to consider a curiously oft debated issue– whether or not squeezing the grain bag following the mash impacted the quality of the finished beer. Initially, the thought of squeezing a full bag of sopping grains suspended over my kettle wasn’t very appealing to me, largely because I prefer cleanliness and precision when brewing, and bag squeezing seemed like a good way to make a mess while simultaneously being less than predictable.

As I dug deeper into the methods, I learned one of the more common reasons advocated for squeezing the bag is that it improves efficiency by extracting more sweet wort from the grains. In fact, BeerSmith’s standard sparge and BIAB methods have grain absorption rates set to 0.96 and 0.586 fluid ounces per ounce of grain, respectively, as it assumes some squeezing when utilizing the BIAB method.

On the other side of aisle, opponents of the practice claim squeezing the bag increases the risk for extracting tannins that could lead to undesirable astringency in the finished beer. With numerous successful BIAB batches under my belt where the bag was left untouched, most achieving adequate efficiency, it was time to see for myself what the impact of squeezing really is!

| PURPOSE |

To evaluate the differences between two beers made using the BIAB method where one was squeezed post-mash while the other was allowed to drain.

| METHODS |

In keeping with my commitment to develop my ideal English Bitter this year, I made some minor adjustments to a prior recipe I enjoyed, tweaking the absorption rates for each batch in BeerSmith to ensure both achieved the same pre-boil volume.

The Bitter Squeeze

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 25.9 IBUs | 8.6 SRM | 1.041 | 1.010 | 4.0 % |

| Actuals | 1.041 | 1.011 | 3.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row) US | 4.375 lbs | 51.08 |

| Pale Malt, Maris Otter | 3.687 lbs | 43.05 |

| Caramel/Crystal Malt - 60L | 7.04 oz | 5.14 |

| BlackPrinz | 1 oz | 0.73 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 7 g | 60 min | Boil | Pellet | 14 |

| Pekko | 7 g | 30 min | Boil | Pellet | 15 |

| Pekko | 11 g | 5 min | Boil | Pellet | 15 |

Notes

| Water Profile: Ca 87 | Mg 0 | Na 8 | SO4 104 | Cl 81 | pH 5.3 |

Download

| Download this recipe's BeerXML file |

I prepared a single large starter of WLP002 English Ale yeast a few days before brewing.

I enlisted the help of my friend, Dave, who arrived early brew day morning as the RO filtered strike water was heating up. While waiting, we milled both sets of pre-measured grain.

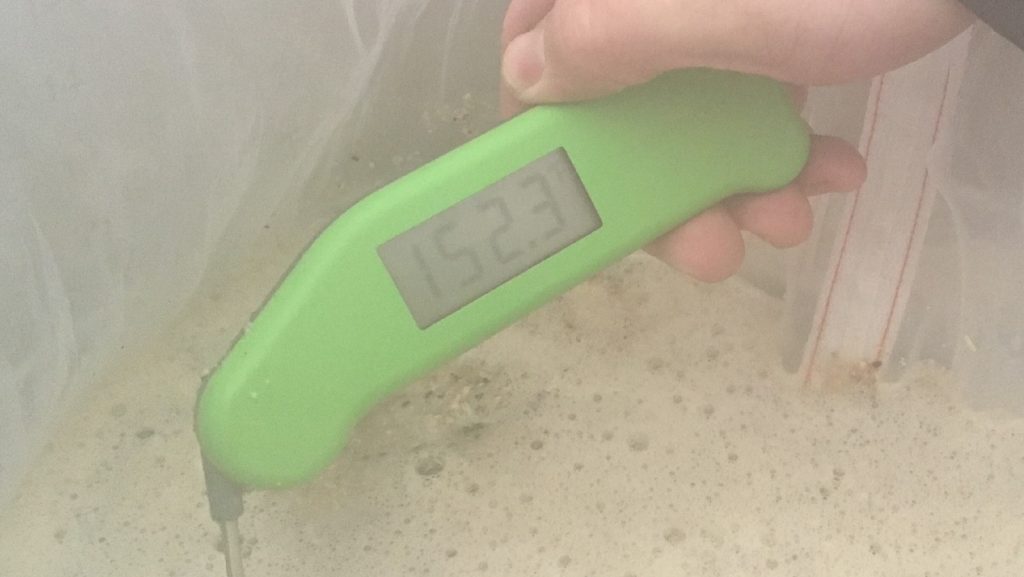

Once the water for each batch had reached the appropriate strike temperature, the grains were mixed in before we checked to ensure the target mash temperature was hit.

I recirculated for the duration of both 60 minute mash rests. Having staggered the start of each batch by a few minutes, I gently hoisted the bag out of the first one that was done mashing, allowing it to slowly drip into the kettle as the wort was being heated to a boil. Similarly, I hoisted the second bag of grains out of the kettle at which point Dave and I took turns squeezing it with as much force as we could until the same pre-boil volume was reached.

After our morning workout, the worts were boiled with hops added per the recipe.

After each batch had boiled for 60 minutes, they were quickly chilled to slightly warmer than my groundwater temperature.

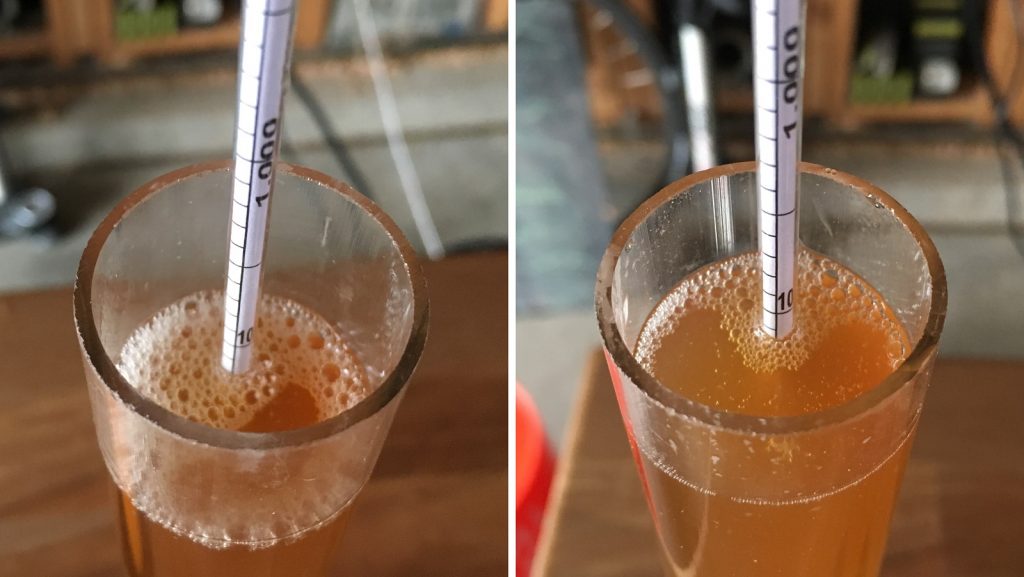

Hydrometer measurements showed both batches had achieved the same OG, indicating similar efficiencies, which at the very least supports the accuracy of the grain absorption rates in BeerSmith.

I filled separate glass carboys with equal volumes of wort from either batch then placed them next to each other in my fermentation chamber to continue chilling. Once both were at 64°F/18°C, I evenly split the decanted starter between them before hitting each with 90 seconds of pure O2. I observed activity in both 12 hours later.

Fermentation appeared to be slowing at 3 days in, which wasn’t unexpected given the lower OG, so I began nudging the temperature in the chamber up in order to encourage complete attenuation and clean-up of any off-flavors. With activity all but absent a couple days later, I took an initial hydrometer measurement that showed FG had indeed been reached; another reading a couple days later showed no change, confirming fermentation was indeed finished.

I proceeded with cold crashing, fining with gelatin, and kegging.

The filled kegs were placed in my keezer where they received a brief period of burst carbonation before the gas was reduced to serving pressure. Interestingly, the non-squeezed beer was crystal clear just days after being kegged while the squeezed beer maintained a noticeable haze.

| RESULTS |

Cheers to The Brew Hut for hosting an awesome Big Brew Day where most of the data for this xBmt was collected!

A total of 27 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer made without squeezing the bag and 2 samples of the squeezed bag beer then asked to identify the sample that was unique. While 14 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance, only 8 picked the odd-beer-out (p=0.72), indicating participants in this xBmt were not able to reliably distinguish a beer produced using the BIAB where the bag was squeezed from a beer made without squeezing the bag.

My Impressions: I simply could not tell these beers apart and was forced to guess in the multiple triangle tests I attempted, failing more than succeeding. To me, these beers were exactly the same in terms of aroma, flavor, and mouthfeel, the only place they were different was in appearance, which didn’t seem to have any impact on other characteristics. Of all the Bitters I’ve made this year, this was easily my favorite! I really enjoyed the dialed down Crystal malt character and the flavor contribution of Pekko hops, despite it being less than traditional for the style.

| DISCUSSION |

Concerns about astringency in beer make sense because it really is quite unpleasant, and hence avoiding practices that might potentially lead to astringency also makes sense. Of the various ways brewers have posited as to how this off-flavor is created, the non-significant results of this xBmt seem to demonstrate that squeezing wort out of a BIAB bag after the mash isn’t one of them and, in fact, supports that claims of bag squeezers that it has no perceptible impact on beer character.

One area it did seem to have an impact is on appearance with the squeezed batch maintaining a slight haze while the non-squeezed beer dropped bright almost immediately after being kegged. This seemed a bit odd to me, as I wasn’t expecting squeezing the bag to have any impact on appearance, so I brewed another batch where I squeezed the bag just to see if that result could be replicated. Lo and behold, the resultant beer had a similar haze that never dropped out. As much as I prefer clear beer, the fact the clarity difference wasn’t enough to make them reliably distinguishable by participants is pretty interesting.

For me, the effort and mess of squeezing the bag combined with the hit to clarity leaves me less than enthusiastic to continue using this method, even if it has no impact on beer character. For those who do prefer squeezing, these results suggest your method is probably a-ok and won’t lead to the mouth-puckering astringency some fear.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

New Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

50 thoughts on “exBEERiment | Brew In A Bag: Impact Squeezing The Bag Has On A Best Bitter”

Very interesting. I squeeze the bag and rarely have any haze issues. Based on your article I probably don’t squeeze as aggressively as you did in this one. Great work keep it up!

This is a really interesting experiment, which matches my experience in terms of not having and issue with tannin extraction but I think it slightly misses the point on how squeezing the bag can improve efficiency.

You aimed for the same pre-boil volume but when I BIAB I squeeze every drop of wort out by twisting the bag and squeezing it like hell. If you squeezed as much wort as possible and then aimed for the same post boil volume, then you would have been more likely to see an improved efficiency.

That is a good point, with Jake adjusted the water volume to reach the same pre-boil, efficiency should be the same. If you start with the same water volume and then squeeze or not, then efficiency difference should be noticeable.

Had I put the same amount of water in each batch the squeeze one would have likely achieved lower efficiency since more volume would dilute the same amount of sugars

To achieve the same amount of pre-boil volume, you would have had to use less water in the squeezin’ one.

Jake – there was roughly 56 oz of wort left in the no-squeeze bag that was exactly the same gravity as the kettle – and both batches had the same pre boil gravity? Assuming you decreased the strike water in the squeeze batch to reach the same boil volume by the same 56 oz the difference between strike water was 112 oz – or close. I’m wondering how you knew how much wort was going to drain without squeezing and did you reach the target boil volume, or did you just let the no squeeze drain – measure – and match the squeeze bag to that volume?

Hi Rex, I didn’t measure how much goes down the drain. The batches used different absorption rates in BS (~.9 and .58) so strike water was slightly different between the two.

No squeeze was hoisted up and left to drip until it about stopped. We squeezed the other batch until nothing more came out. Pre boil volumes were the same between each, did not measure gravity but it would have to be the same I guess since boil off is the same.

This is a good point actually. More sweet wort extracted vs. same boil volume since you’re brewing a predetermined size batch.

Excelent xbmt. All my batches have been made squeezing the bag, and all of them have some level of haze. I suppose the fact that my milling has to do with it, I mill very fine, almost flourish, maybe that allow more protein to pass through the husks/bag. Maybe another xmbt correlating bag squeezing with mill gap?

Keep up the good work!!!!

Based on my research, as documented in the latest edition of HtB, squeezing matters most for porters and stouts where you are using a significant portion of roast malt. Your recipe used a mere 1 oz of roasted wheat, so I expected no difference in taste. The difference in clarity is interesting though.

“squeezing matters most for porters and stouts where you are using a significant portion of roast malt. ”

Matters in that it makes better beer or worse beer?

Or perhaps I need to buy the book to unravel that mystery. Been meaning to, anyway. 😉

Thanks for reading John! I still need to pick up a copy of the new HtB. Interesting your thoughts on roasted grains. I’ve been pining for a nice dry Irish stout, may need to do a follow up xbmt with a 85/15 MO & blackprinz to give this a try.

Question: You squeezed one bag but did not squeeze the other, yet you ended up with the same pre-boil volume for each batch. Something ain’t right there, methinks.

I performed a little experiment a few times where I decided not to Squeeze The Bag (STB) and just let it drain for the 20 minutes (or so) to get to boil. Then I STB over a separate container and only got perhaps 2 cups of wort. So I decided that STB wasn’t really worth it for that small amount of wort.

But I cannot NOT STB. I just can’t. So I continue to STB and most of my beers have a bit of haze. My Pale Ales do not, though. They are always clear as a bell. Same for a recent Kolsch.

But anyway, you HAD to have some volume difference between the two batches. Perhaps that 2-ish cups just isn’t enough to really register in the kettle?

So what is it in that 2 cups of concentrated wort that causes the haze, I wonder? I must be a specific grain because, as I said, my pales and a kolsch came out fairly clear. At least I think so. I will need to make sure I’m not deceiving myself.

So I guess that, as always, more data points are needed.

Absorption rates were adjusted in BS to make sure pre boil volume was the same. It’s like .9 v .5 if I recall correctly off the top of my head, not sure something wasn’t right since I aimed for that specifically.

This is interesting. I’ve been doing BIAB for about 6-7 years and the only times I ever have haze are when the yeast won’t settle out (e.g. Kolsch strains). I don’t fine with gelatin or any other clarifiers post fermentation, and still reliably get very clear to brilliant beer.

Could your haze be due to a pH issue? Or maybe it needs a little more time to condition?

I doubt it was due to a pH issue. No sparging doesn’t really lend itself to massively high pH. Every squeezed batch I’ve done has now had a level of haze which wouldn’t really go away. They aren’t like super hazy per se, if you were to drink the beer on the right in the pic alone it seems pretty clear actually. Only in comparison to the non squeezed was it noticeably hazier which made me hyper sensitive to haze in subsequent beers.

This idea is limited in volume and so is not in the spirit of triangle tests with a significant number of tasters:

What if you squeezed the bag into a starter flask and then obtained an equivalent volume from the main wort into a second flask. Then you could boil, add hops and finally compare the result of the two nano fermentations. Would you be able to taste the difference then?

I’m sure there would be a yuge difference. The wort form the squeezins is concentrated. My pre boil gravity (for a 1.050 beer) is something like 1.035 before I squeeze, then on the mark afterwards.

I constantly freak myself out a little by measuring gravity and forgetting that I hadn’t squeezed the bag yet. 😉

So what were you brewhouse efficiencies for each method? I squeeze and double crush and routinely get high 70s to low 80s on a medium gravity batch. Slightly higher for low gravity and slightly lower for high gravity. I have my absorption rates and final fermenter volumes so dialed in with the priceless biab calc that I doubt I will change me method. I use thermal gloves and a stainless grill rack over my wide 15 gallon kettle and rarely lose a drop of wort. Cool exp

Hi Jake. Nice exbeeriment. Very interesting finding on the haze and confirming the beers were indistinguishable. However, the article skips over the efficiency difference of the 2 batches, which is the reason people actually squeeze. Also it didn’t really cover how you achieved the same preboil volume. Obviously you must have added more water to the mash of the no squeeze, but did you also adjust the grain bill as well? I think adding a paragraph on your adjustments to the no squeeze batch and then one covering the efficiency difference would be a great addition to the article. My .02 🙂 Thanks!

I’ve the same question, Matt. See my post above.

I compared the volumes of a “squeeze” versus a “no squeeze” a couple of times. If I simply let the bag drain for the 20 minutes it takes to get to a boil, then remove that bag and squeeze it over a bucket, I only get perhaps a cup, maybe two, of wort.

So maybe the absence of that small amount of wort is not enough to register in the kettle?

Next brew, I’m going to measure the gravity of that remaining unsqueezed wort, then calculate what kind of effect that would have on the overall pre-boil gravity. I can’t imagine it would be that much but evidently has enough of something in it to cause haze.

Thanks for reading.

There were no grain bill adjustments. The only different input was water based on the BS absorption rates for each method. Mash Efficiency was the same between the batches, brewhouse efficiency I believe would be different based on lower input of water in one, but I don’t ever calc BH efficiency so am not entirely sure of the formula.

Wow! That is a game changer. Less work AND clearer results! Thanks for the clarification (pun not indended) 🙂

I have always squeezed the bag even with stouts and porters. I usually let it drain for 5-10 min.then squeeze. I very rarely have any haze. Thanks for the exbeeriment, it’s always good to try things and see what happens.

Can you advise where in Beersmith you find the absorption rate please?

It’s in the advanced settings. Marshall has a video walk through of it posted on YouTube if you search for beersmith tutorial brulosophy.

If the efficiency is the same, no grain change, no difference in the beers, but more haze, why bother squeezing? I BIAB and squeeze it most of the times, and my efficiency improves a lot doing it. Anyway thanks for the exbeeriment.

Do you know what the mill gap was set at? Thanks.

Credit card width, I’m not sure what that is exactly but I believe 0.30

Some surprising results here! The final gravity reading was quite interesting, as well as the clarity. Perhaps both can be explained by squeezing more proteins into the wort? Proteins and polyphenols together can cause haze, so this would be a reasonable cause. I am not sure if proteins could cause that much of a FG reading.

This is a great experiment, many thanks Jake!

I’ve often wondered if squeezing affects clarity, as the squeezed wort does look like pea soup compared to the relatively clear main body of wort. When working with very large grain bills, I would not like to miss out the squeeze step, as there is so much high gravity wort left in grains, it is too wasteful to just chuck it out.

Now that it seems it does have something to do with clarity, I will be motivated to do my squeezing over a clean bucket, and I will pour into a glass beaker to see if the solids, whatever they are, might settle out over the next half an hour or so, while the main wort is coming up to the boil or boiling, so that I can then pour clear wort into the boil.

The other idea would be to filter it, maybe just a clean chux wipe strapped over a container in a funnel shape would do the trick as well.

Your experiment has also caused me to re-think when i stir the mash. I also have a re-circulating 1V system, (when stepping and mashing it’s powered by a stainless external HERMS coil sitting in a domestic 1.7 litre kettle)

The wort is crystal clear by the end of the full volume mash, but clouds up again when I stir it before the ramp to mashout at approx 78C or 172F. Even though it’s circulating through the ramp to mashout, the approx 8 mins of recirc is not enough to clear up the wort. Maybe I’ll forget about stirring then, (stir earlier during the middle of the mash) to aim for clearer wort.

Anyone care to comment on how likely the solids are to settle out in wort that has not been boiled? I guess there has been no hot break to coagulate the proteins and no irish moss etc..

Raise the bag – squeeze – dump grains – stir to center any break material – wait ten minutes. The solids created by the squeezing coagulate along with the rest of the break matter and the wort runs clear.

BIAB Pro Tip:

More better to hoist the bag and rotate repeatedly around its axis to extract more wort v. the less efficient and much more messy bag-squeezing method.

Same holds true for getting the most from your dry-hop sac.

Hoist’n rotate FTW!

That technique produces horizontal stress on the bag seams and will lead to splitting.

Hi Jake. Nice exbeeriment. I have a question for you, sorry it’s a little off topic. Can you tell me where you place your temp probe with your new eBIAB recirculating system? If I place my temp probe from the controller in my grain it over fires my elements and my efficiencies go to hell. I ended up placing the probe from the controller below my grain basket and placing a second separate temp probe in the grain and monitor the whole system manually. I hit all my numbers this way but it is a little intense at times. Cheers!

Sure, right now the probe is just below the grain bag, there is a false bottom in there. I bought two new probes which I plan on putting in a T valve off of the return port for mash recirculation.

Thanks for to quick response. I too have a false bottom and that is where my probe is placed. It seems strange that my grain bed is about 4 to 6 degrees cooler than my controller temp probe, even towards the end of my mash time. Any thoughts on this?

I would guess it has to do with lack of insulation. My setup has not been as precise as I had hoped with mash temp holding, looking at getting some kind of yoga mats or something to wrap it in to hold temps better. I also think it could be due to the fact that the probe is not reading actively flowing wort which is the main reason I’m going to go to a second probe on the recirc loop.

Thanks again. Super website, you guys have improved my success rate 10 fold 🍻

10mm thick yoga mat from k-mart, $10, made of nitrile closed cell foam rubber, this stuff is rated to 120°c or 248°F. Has lasted on the outside of my turkey fryer based 1V electric HERMS for 54 batches and still going strong. Photo here https://club.coopers.com.au/static/media/attachments/1493620226_57_120.JPG

I have noticed much more accurate temps throughout mash, when changing from thermowell in wort under grain bed, to thermowell in t-junction at the exit of the small stainless HERMS coil, where the wort returns to the top of the grain bed.

That little stainless coil can raise the temp of 28 litres or about 7 gallons of wort, by 1°C/min (about 1.8°F/min) when stuck into a $7.50 Target cheapie plastic 2200W 1.7 litre kettle. No risk of scorching for steps, you can use rye, rolled wheat, polenta, burgul, rolled oats with no fear of scorching on the electric element. No need for special high current circuits.

Back on topic, for my next brew, I am going to squeeze grains but over another vessel, then pour the cloudy wort into a large transparent beaker and see if I can get the solids to settle out then pour the (hopefully) clear amount back in to boil. Will report back here with how that goes.

Anecdotal: I squeeze the shit out of my bag. Just last night I enjoyed a bottled Pliny clone, a pilsner, and a Kolsch. My pils was cloudy when I first bottled it (I bottled after only two weeks of conditioning) but it is VERY clear now. My Pliny and kolsch were clear as a bell as soon as they were conditioned in the bottles.

Maybe all beer will clear if you just give it time? So, yeah, more data is needed on this Xbmt.

I have been BIAB for years and never felt that I had an issue with astringency or similar issues. I don’t squeeze the bag anymore however, since the simple act of lifting the bag out of the wort causes the bag to compress the grains and “self squeeze”.

I either suspend it above the mash tun for a few minutes to allow most of the free wort to drip out, or more commonly, put it in a clean bucket then dump that free wort into the kettle just before it comes to a boil.

Unless you drain you mash tun from below and leave the grains and bag fully suspended in wort that you don’t collect (as many fly spargers might do), your getting a squeeze. I can’t imagine what physical process could preferentially squeeze more tannins from the grains without having first gone through multiple sparges.

I didn’t expect any flavor difference, but seemingly every beer these days has oak, fruit or a ton of hops added, so tannins are clearly an acceptable outcome.

Thanks for the writeup! I BIAB and while I didn’t think I squeezed the bag all that much, my grain absorption numbers say differently. I fine with gelatin and bottle, and I’ve noticed a haze in many of my beers that can take 6-8 weeks in bottle to really start settling out. I can only be patient so long, and normally start drinking them after about 4 weeks, so for my next batch I think I will try less squeezing.

Other than stouts, I’ve never had beers last 6 to 8 weeks! But I squeeze everything. Hard. About half my beers are crystal clear and the other half retain an annoying haze no matter how long I chill. Styles range from a clear Kolsh and Pliny clone to a hazy ESB and APA. All run through my mill twice at the thinnest setting.

So, I suspect there is some particular grain that is causing the haze. Perhaps I can coax that grain from my recipes and test that theory.

Until then, I’m going to try really hard to NOT squeeze my next few batches (it’s really difficult for me to no squeeze) and see if there is a noticeable (p=>05 😉 ) difference.

Bag squeezer here, but that’s not what I’m here to say, you proclaim using white labs 002 but have a bag of wyeast next to your starter or am I missing something? Cheers keep up the good work.

I squeeze the bag. Actually, I twirl the bag till it gets super tight. If you talk to Rex Slagel, he’ll give you the science behind this. Effectively, you aren’t putting enough pressure on individual grains of malt (etc.) to extract any tannins from them. Also, squeezing the bag pushes some of the fines that were filtered back into the beer…thus the haze. When I brew, I recirc, and the beer before squeezing is almost crystal clear…after I squeeze it’s significantly murkier.

Personally, after I lifted the bag, I lay it on some bbq grid above the kettle and spread it like a thick pancake.

I sparge directly on this with the shower at max temp (140F/60°C) and squeeze like crazy by twisting the top of the bag and putting all my weight on it.

I repeat this sparge and squeeze operation 3 times, which means I don’t need to add too much water to reach my desired pre-boil volume.

I always get around 79% brewhouse eff with this technique and never get off-flavors.

No need to heat the sparge water in a separate kettle, great eff, simple process, nothing to complain about.

Personally, after I lifted the bag, I lay it on some bbq grid above the kettle and spread it like a thick pancake.

I sparge directly on this with the shower at max temp (140F/60°C) and squeeze like crazy by twisting the top of the bag and putting all my weight on it.

I repeat this sparge and squeeze operation 3 times, which means I don’t need to add too much water to reach my desired pre-boil volume.

I always get around 79% brewhouse eff with this technique and never get off-flavors.

No need to heat the sparge water in a separate kettle, great eff, simple process, nothing to complain about.

I do 10 gallon eBIAB batches and I allow the bag to rest in my basket for 15 min or so while bringing up to boil temps. Then i put the basket on top of a big bucket and allow to drain for about another 15 at which time I dispose of my grains. Then I put the wort back into the beer. Works like a champ! I gave up squeezing because the grains are hot and it’s hard to squeeze at eye-level with sticky wort running down your gloves and onto your arms.