Author: Ray Found

I’ve always mashed with a liquor-to-grist ratio of 1.25 quarts per pound of grain. Why? It was the example provided in my favored strike water calculator, and it never presented a problem. That is, up until I tried making a 10 gallon batch of a high OG beer using a 48 quart converted cooler MLT— there was no way all that grain and water was going to fit in the tun. Thickening the mash to 1 qt/lb and making two passes with sparge water helped me get through the brew day, though I wondered how this change from my normal process might impact the beer. It turned out totally fine.

Liquor-to-grist ratio is a fairly commonly discussed issue among brewers, with claims the thickness of a mash is directly correlated to wort quality. However, a growing number of anecdotal reports from brewers seem to suggest liquor-to-grist ratio may not as critical an element as we’ve been led to believe. From BIAB and no sparge brewers performing full volume mashes with ratios as high as 2 qts/lb to batch and fly sparge brewers mashing at 1 qt/lb in an attempt to squeeze as much grist into their tuns as possible, the range is vast and yet people are making good beer. Indeed, brewers are manipulating mash thickness for myriad reasons, but does it actually have a noticeable effect on the beers we’re producing?

| PURPOSE |

To evaluate any potential perceptual differences between two beers of the same exact recipe mashed with different liquor-to-grist ratios.

| METHOD |

For the 2014 holidays, I made a simple, minimally bittered American Pale Ale with Citra and Amarillo that ended up being one of the fastest kicking kegs I’ve ever put on tap. For this year’s festivities, I decided to make a similar beer utilizing hops I’d heard a lot about but never tried first hand, Rakau and Galaxy.

Southern Summer Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 90 min | 46.1 IBUs | 5.4 SRM | 1.050 | 1.010 | 5.1 % |

| Actuals | 1.05 | 1.012 | 5.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsen (Dingemans) | 9.7 lbs | 48.27 |

| Vienna Malt (Gambrinus) | 5.169 lbs | 25.72 |

| Pilsner (2 row) (Gambrinus) | 4.4 lbs | 21.89 |

| Honey Malt | 13.23 oz | 4.12 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 20 g | 60 min | Boil | Pellet | 12.1 |

| Galaxy | 30 g | 15 min | Boil | Pellet | 14 |

| Rakau (Alpharoma) | 15 g | 15 min | Boil | Pellet | 10.5 |

| Galaxy | 60 g | 15 min | Aroma | Pellet | 14 |

| Rakau (Alpharoma) | 20 g | 15 min | Aroma | Pellet | 10.5 |

| Galaxy | 100 g | 0 min | Dry Hop | Pellet | 14 |

| Rakau (Alpharoma) | 60 g | 0 min | Dry Hop | Pellet | 10.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| San Diego Super Yeast (WLP090) | White Labs | 80% | 65°F - 68°F |

Notes

| Hop Stand 185F |

Download

| Download this recipe's BeerXML file |

Since this was for the holidays and I wanted a spare keg for my sister-in-law’s wedding, a dual 10 gallon batch brew day was in order. I used Brewhead’s Batch Sparge calculator to outline the differing mash temps and set to the task of mashing in both batches.

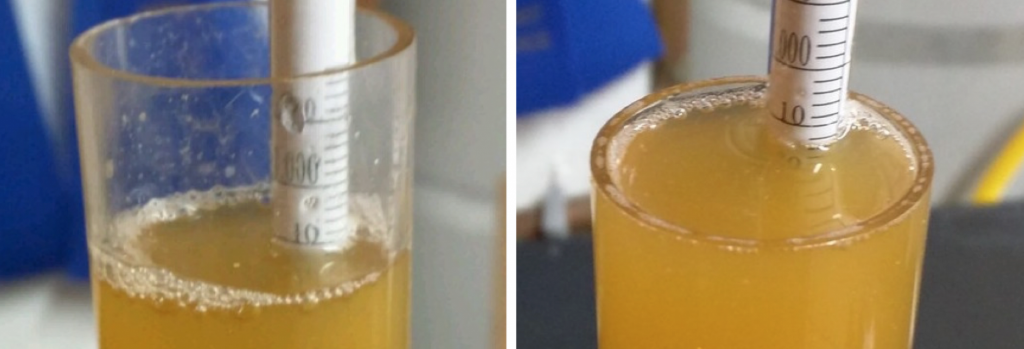

With the parameters dialed in for my normal 1.25 qt/lb mash procedure, I easily hit my target mash temperature. As a relative novice to the world of thin mashing, my calculations for the batch with a 2.5 qt/lb ratio were ever so slightly off, though not by enough to cause me too much concern, and the mash was decidedly closer to the rim of my tun.

I used the batch sparge method for these beers, which involved collecting the first runnings, stirring in a sparge addition, letting the mash settle for a few minutes, a brief vorlauf, then collecting the rest of the sweet wort.

Both beers went through a 1 hour boil during which hops were added at the prescribed times, then they were chilled to 185°F/85°C, the temperature the hop stand hops were allowed to steep. Finally, I finished chilling and took a hydrometer reading, noting a minor SG difference. Did mash thickness have anything to do with this?

I proceeded to transfer each wort into 6 gallon PET carboys that were placed in temperature controlled chambers. Each fermentor was then pitched with a vitality starter of WLP090 San Diego Super Yeast. Within 48 hours, both batches appeared to have reached high kräusen.

I dry hopped the beers 4 days into fermentation, noticing the activity had slowed dramatically. Three days later, I took a hydrometer reading that revealed a small difference with the standard mash beer dropping to 1.010 SG while the thin mash beer was at 1.012 SG.

It seems odd that a 0.7°F/0.4°C difference in mash temperature would produce such disparity and I personally suspect something else was at play, likely the variable of focus, but I can’t be certain. The beers were cold crashed, fined with gelatin, transferred to kegs, then placed in my cool keezer where they were force carbonated. When it came time to collect data, both beers had a similar hop haze and were tasting delicious.

| RESULTS |

A total of 24 friends, family, and BeerMe Brew Club members participated in this xBmt, each one blindly presented with two samples of the thin mash beer and one of the standard mash thickness beer. Given the sample size, 14 tasters would be required to correctly identify the different beer to achieve statistical significance (p<0.05). When the dust settled, only 5 of the 24 tasters made the correct selection (p=0.90). These results suggest that in this particular xBmt with this particular recipe, this particular set of participants were not reliably able to distinguish between a beer mashed with a more normal liquor-to-grist ratio and one mashed thin.

My Impressions: The same. That’s my impression– these beers were exactly the same. Despite the 0.4% difference in ABV, I perceived the flavor, aroma, and mouthfeel of these beers as identical. Back-to-back, side-to-side, in a triangle… didn’t matter. In all of my trials, I never had a clue which beer was which, I could not reliably tell a difference.

| DISCUSSION |

We often caution readers not to make the mistake of misinterpreting non-significant results as meaning the variable has no impact. This is a good example of that– liquor-to-grist ratio did appear to produce a measurable difference in attenuation, albeit a small one, and I was somewhat surprised this didn’t impact perceptual characteristics. However, based on my personal experience and the results of the blind tasters, I’m left with the distinct impression mash thickness had little if any impact on the perceived quality of the final product. Having tasted great beers mashed at varying thicknesses, it’s hard for me not to view stressing over achieving a precise liquor-to-grist ratio as futile, though perhaps we’ll discover something different in future iterations of this xBmt.

One thing to consider when messing around with liquor-to-grist ratio, at least for those concerned about water chemistry, is that different mash thicknesses will produce different pH levels.

Ultimately, if liquor-to-grist ratio impacts the perceptual qualities of beer, I have to believe it’s well down the list of things to worry about, which is a relief! It means, to me, that we as brewers can be free to tailor our mash thickness to what’s being brewed or just to simplify the process without fear it will fuck up the beer. Whether a full volume BIAB or a thick mash Barleywine, the end result will be beer whose quality is likely determined by factors other than the ratio of liquor-to-grist.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

New Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

42 thoughts on “exBEERiment | The Mash: Standard vs. Thin Liquor-to-Grist Ratio In An American Pale Ale”

You’ve probably seen this…

http://braukaiser.com/wiki/index.php?title=Effects_of_mash_parameters_on_fermentability_and_efficiency_in_single_infusion_mashing#Mash_thickness

I have been doing some no spare batches, and mash conversion efficiency can suffer a bit in my experience, but it’s very minimal. Never noticed attenuation differences that I thought were significant

I’ve scene some small 0.001-0.002 changes with grist ratio. Often if I’m thinner it’s coupled with another variable though, infusion, decoct, etc, so it’s truly hard to say definitively.

You mentioned the mash pH discrepancy in your discussion, but did you make those changes in the mash’s for these beers?

Yeah, so both beers had water acidified with the same amount of acid per gallon, which meant that the input water was the same for both. Bru’n water speadsheet calculated the pH equally at 5.3. While I didn’t record pH measurements this brewday, every single time I have used Bru’n Water and built my water from RO, it matches the predicted pH within the precision allowed by my cheap-o meter. (ie: 5.3 in the calculations, reads as 5.27-5.33)

Hey you listed all four boil additions @ 15 in the recipe…I assume this isn’t correct.

It’s my non-educated opinion that based on Troester’s results confirming that mash thickness is irrelevant to conversion, that the “standard” 1.25-50 ratio is a result of protecting the pickup / runoff from clogging. It seems no one really knows why this ratio is the given except that when pushed higher the occurrence of a stuck sparge increases. There is some banter regarding enzyme / starch proximity relative to mash thickness, but that is yet unproven as well.

Next up, same exbeeriment aimed at mill gap setting relative to kettle efficiency.

Do you mean like this? https://brulosophy.com/2015/11/23/mind-the-gap-course-vs-fine-crush-exbeeriment-results/

Or were you thinking something different?

Yeah, read this article – there is no mention of the WTGR.

I have always speculated that the water to grist ratios come from a time when brewers made multiple batches from one set of grains. Moving from highest gravity to lowest gravity. In my research and to my understanding they made less of the higher richer og beers and much more of the medium og beers, and lastly less of the lower kinderbier or table beers. I have no evidence to back this theory up, nor does anyone that I can find. Other than anecdotal; recipies, notes etc… When they made 1 beer it was a blend of the 3, and therefore our modern sparging techniques were born. Again just historical (and causal) speculation. I play with my grist ratios all the time. I generally BIAB, but I also No Sparge in a cooler, for higher OG beers, and for certain step mashes.

Excited for the mill gap settings efficiency xbrmnt. I noticed a dramatic improvement in efficiency when I went to .35.

My mill is now set to .020 – go for it.

I brew with a Braumeister all-in-one brewing system and have been doing full volume mashes for some time now vs. a sparge at the end of the mash. There has been no change in my beer and they have turned out great. An added bonus is that my brew day has shortened. Win/win in my books.

What was the sparge volume left for the batch with a 2.5 qt/lb ratio? Compared to the regular mash?

Did you end up taking a mash ph measurement of both?

I used to religiously go for a 1.25:1 ratio, then I got grey hairs because the mash temp (which apparently isn’t that important) would be a degree or two off, so I’d add ice or boiling water to get it exactly right. Now, I just make an educated guess of how much strike water at x degrees calculated for a 1.25 ratio will be required, add my sparge water and required mash-out volume, and turn the heat on. Then, when the temperature gets to x, I start adding water to the grist until it hits my target temp. Then, whatever is left over, I bring to 178 or so and transfer the amount of sparge water to the HLT (it cools significantly in there). Whatever is left over, I bring to a boil so I can do a mash-out with it. Once all that stuff’s done, I dump anything left over and use it as my boil kettle. It’s much less stressful that way. Based on the above, I have no idea what my ratio ends up being and I have never – in 20 years of brewing – measured my pH.

Mash differences should be tested with a very low hop volume. While these beers were (I’m sure) very tasty, the recipe is dominated by a hop character that tends to mask the malt character. Since there are no hops in the mash, the fewer hops in the finished beer would provide a better test recipe.

Came here to make the exact same comment. Why cover up what you’re trying to see the differences in by overhopping? imagine trying to do a single hop difference experiment with 20% roast malt. the hops would be obliterated by the roast. here you did the opposite.

You mentioned “I might need to add 2 mL of lactic acid to get to 5.2 pH at a standard mash thickness (e.g., batch sparge), the thin mash of a no sparge batch might require no acid addition.”

This seems counter-intuitive to me. With a thinner mash, you’ve got more water (around pH 7.0), so it seems like a thinner mash would have a HIGHER pH and would require MORE acid to bring it down. Am I missing something?

I’ve been brewing BIAB for years and I don’t really do any acid additions, for what it’s worth, other than the occasional addition of a small amount of acid malt to my grist for a very pale beer like a 100% Pils grist (usually 2 oz acid malt). I’m not sure it really makes a difference. It just makes me feel better.

I think it’s more a function of starting water chemistry, as I’ve experienced the same thing.

So you’ve seen a lower pH (without acid adjustment) with a thinner mash?

Often, yeah. I rarely have to add acid when no sparge brewing, while I almost always have to when batch sparging.

Fascinating! I’ve been assuming that BIAB brewing would result in higher pH wort because of the high volume of water. I’ve resolved myself to just not care, since I brew good beer with the BIAB method and lots of other people do, too, but I just assumed my pH would be higher as a result.

A lot of the reason to be concerned about mash pH is because of the affect that sparging will have on the pH. Since BIAB has no “sparge” in the traditional sense, but has a “passive sparge” throughout the mash process, I think it probably doesn’t really matter so much. The wort is at the same pH (or slowly lowering) and isn’t going to be hit with high pH sparge water at any point, so it is safe from the “dreaded tannin extraction of doom” that people are so concerned about, in regards to high pH as a result of over-sparging.

Easy enough to treat the sparge water to match the pH of the mash, but certainly your point about no change in pH due to full volume mashing is worth noting as well.

Really depends on the grist and starting water.

It’s great to finally see experimental confirmation of what no-sparge and BIAB brewers have long suspected, which is that the liquor-to-grist ratio in the mash simply doesn’t matter.

Actually – it does matter. Using the link above you can find this – much the opposite of common knowledge – “A significant difference was however found in the efficiency. The brewhouse efficiency of the tick mashes remained almost constant between 58 and 60% over the temperature range of the experiments, but the brewhouse efficiency for the thinner mash showed a strong dependency on the temperature and was always better than the efficiency of the tick mash. That leads to the conclusion that thinner mashes perform better and allow for better extraction of the grain. Briggs also reports that thinner mashes can convert more starch but that most of the conversion potential is reached at a water to grist ratio of 2.5 l/kg [Briggs, 2004]”

Bear in mind though that thick mashes are followed by bigger sparges than thin ones, so what you lose in efficiency in the mash is gained back in the sparge.

You’ll need to help me understand that – lost efficiency is gained?

I think what you’re saying is the true gravity of a brew is not revealed until the sparge is complete, whereas the true gravity of a no-sparge can be measured at any time. But here’s a fundamental flaw when sparging that most folks ignore. The transfer of sugars ends when the boil kettle is full, or when the pH rises above 6 and unless the sparge water is treated there is a pH rise curve that impacts the final product, meaning mash pH is no longer kettle pH.

This exbeeriment provides enough data to hinge the following on. Higher WTGR and a finer grind expose more starch, and the available starch converts more fully in the same amount of time and is revealed in the higher SG. So, even if the “lost” efficiency is recaptured when sparging, the total dilution into the boil kettle is never recovered. Also, and typically when employing a sparge, the first 2-3 quarts of wort which contain the highest % of sugars are drawn off and added back to the mash tun – to be diluted by the sparge water.

Post boil SG was higher for the thick mash in the exbeeriment, so brewhouse efficiency was higher, even though conversion may well have been more efficient in the thin mash. Sparge vol for the thick mash was about twice that for the thin mash, which explains why. But the difference is small. As I said above, water to grist ratio really doesn’t matter – you can mash as thick or thin as you want and you’ll get the same beer.

Water treatment for pale beers is important whether or not you sparge. Mash pH is higher in a thin mash, but pH rises higher still when sparging after a thick mash.

Here’s an interesting bit – the WTGR of the thin mash was 2.5 which = 12.08 gallons. A ten gal batch requires about 12.5 gallons in the boil kettle accounting for evap & trub loss. The brew sheets are tough to read, but I think he added another 3.15 gallons to the thin mash as sparge? The question is – how much wort was left in the mash tun of each brew and what was the gravity of that wort? Point is, the thin mash was already diluted and it was ?? within 1 gal of boil kettle volume prior to adding 3.15 gallons of sparge water, so the pre boil gravity was diluted by an unnecessary 2 gallons and left in the tun – ??

@thebrewbag – yes, 12.56 gallons into the tun with the thin mash, and sparged with additional 3.15gallons. This yielded 13.5 gallons pre-boil HOT VOLUME (same as the normal thickness), which I boiled for 90minutes, and finished with 12 Gallons HOT in the kettle -.5gallons cooling shrinkage, and 11 into the fermenters on each batch.

Each batch would see about 2.5 gallons lost to grain absorption.

If you want to maximize efficiency from a single batch sparge, there’s probably an optimum ratio of mash & sparge volumes to use, but I don’t know what it is. Clearly a no-sparge mash will have lower efficiency than a mash with a sparge, since no-sparge leaves undiluted wort behind in the spent grain. A very small sparge will give slightly higher efficiency, and a larger sparge higher efficiency still. I suspect thick mash & large sparge is most efficient, but there’s probably very little in it – maybe a few cents worth of grain.

Interesting that you say that, as most folks understand it the same way. I have 35 records from a no sparge BIAB brewer that average 78.5% and my personal records reflect the same. Obviously we don’t know what the numbers would be using any other method, but when I read the recipes in various magazines, rarely do I see BE above 75%, and most are 72%, so I assume that to be an average using any type of sparge method.

I get about 82-83% efficiency using about 80% of my total liquor volume in the mash (thin mash) and then the remaining 20% for a quick sparge. When I do no sparge mashes I get 70-75% efficiency. I don’t think I’d see a significant improvement from a thicker mash.

One thing to bear in mind is that efficiency of no-sparge mashes varies depending on the gravity of the beer. If you no-sparge a very high gravity beer, you’re leaving a lot of sugar behind in the spent grain because (a) there’s a lot of spent grain and (b) the wort is very rich. Sparging definitely makes sense for high-gravity brewing. For ordinary beer or low abv beer it’s much less important.

I have seen some things suggest that equal running volumes from mash and sparge are the most efficient.

Thanks, I’ll give that a go next time and see what efficiency I get.

Long ago I talked to an award winning brewer who put the grain in then a LOT of water at temp and didn’t even mix. I do mix but not a lot. It is SO much simpler to crush the grain into the MT and then add the water. You could of course measure the water going in but that would cool it and add another layer of uncertainty and complexity. Then BIAB came along and they were doing the same thing. When you add the water to the grain it doesn’t form dough balls, at least not in my experience. In cooking that is the way you do it because if you add the dry to the wet it takes a lot of work to get it to mix, so it always made sense to me to do it that way in brewing.

So I crush into the MT and fill up the cooler with strike water. In the 5gal cooler I go to the top but in the 10gal I leave some space unless it’s a really BIG beer.

I LOVE that for most of these experiments Papazian’s motto seems to apply.

I’m a bit on the extreme here. I do BIAB on my stove and as such it’s full volume. Typically it’s not uncommon for me to have a ratio of 2.8-3. I’d like to think that my beers have turned out well, and placed decently in competition. I do wonder if they would be any better with a lower ratio, but I’d have to change my whole set up.

Max @ http://www.thebeginnersbrew.com

My pump broke before my last brew day. I have a huge 30 gallon mash tun and pump out of that into my kettle. This forced me to do a no spare with a 2.9 liquor to grist ratio which I was very concerned about. My buddy and I just lifted the mash tun onto the bed of his truck which was about equal level to the kettle and we ran off that way. My finished beer ended up being 1.012 instead of 1.010 which is what this article also found. Initial tasting of the un carbed beer seems totally normal so we will see how it turns out. This gives me a little relief though.

Just an update. The beer turned out really well. It tastes great. One knock I have on it as that it doesn’t form a very good head on it for some reason even though there seems to be plenty of carbonation in the beer. I’m not sure if this had anything to do with the water ratio or not. Otherwise, it’s a pretty awesome beer. I’d have to do a test side by side with the same beer recipe with a 1.5 ratio in order to tell if there is a substantial difference though. However, I can attest that I still made good beer at 2.9 for what it’s worth.

The reason I do lower mash-in liquor to grist ratios is so I can do stepped mashes more effectively. The lower mass allows me to get to the next mash temp quickly. If the temperature step change is large, (e.g. acid/protein rest to sach rest) then I can do that using a bit more hot water in combination with the heat source and still have plenty of water for sparge.

I’ve been no sparge BIAB brewing on small batches for a while now. I used to brew on a 3 vessel system, but I rarely have time for a 6 hour brew day. I typically get 70%-75% efficiency consistently. It’s no worse than I would get batch sparging. I usually mash 4 gallons of water to 5-6 lbs of grain. I treat the full volume with mineral and phosphoric acid additions to get the right mineral content and pH. My results are consistent and I typically finish in 2-3 hours. I’ve occasionally seen a 1 point FG miss based on calculated FG, but not consistently enough to believe it’s due to the grist-water ratio. I would be more inclined to believe the gravity misses are caused by some other variable like mash temp or water chemistry as you discussed in your conclusions. Keep up the good work on these. Regardless of the results, you guys help remind homebrewers that making beer doesn’t need to be hard. You mix water and grain, boil with hops, add the yeast and leave it alone. Voila, beer.

What everybody seems to forget is that homebrewers don’t stir continuously, so that the grist sinks to the bottom, and there always has a constant water/grist ratio. So, if the supernatant is 2 cm high, or 4 cm, or 6 cm, it really doesn’t matter. And that is why the water/grist ratio does not matter in homebrewing.